US 73 D Ex

JP00595| Mechanikai adatok | |

|---|---|

| Szivattyú | függőlegesen egyfokozatú |

| Rb-védelem | rb-védelemmel |

| Szabad átmenet | 30 mm |

| Csapágy | Zsírkenésű golyóscsapágyak |

| Motoroldali tömítés | 2-szeres tengelytömítés |

| Olajkamra | igen |

| Közegoldali tömítés | SiC csúszógyűrűs tömítés |

| Szárazmenetbiztos | igen |

| Tengely | Nemesacél |

| Járókerék | Vortex-járókerék, GFK |

| Motorház | szürkeöntvény |

| Elárasztható | igen |

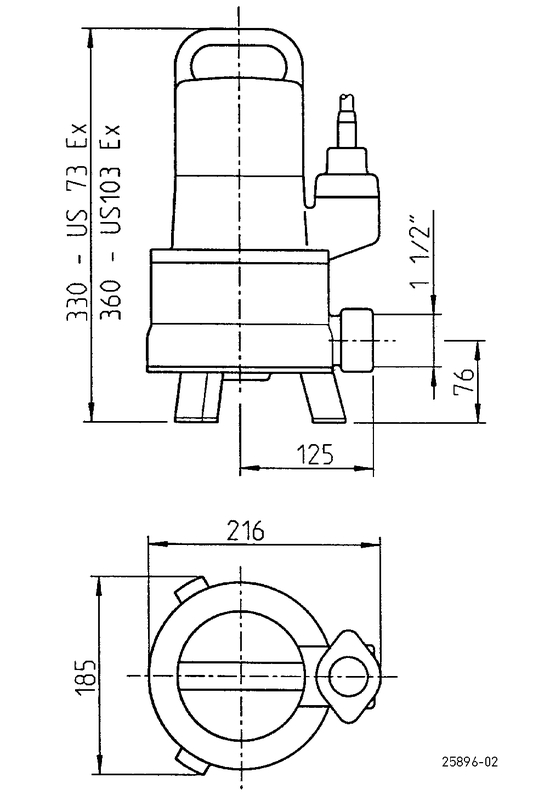

| Nyomócsonk | IG 1 1/2" |

| Súly | 19 kg |

| Villamos adatok | |

|---|---|

| Feszültség | 3/PE~400 V |

| Motorteljesítmény P1 | 0,85 kW |

| Motorteljesítmény P2 | 0,6 kW |

| Áram | 1,4 A |

| Hálózati vezeték | 10m H07RN-F |

| Kábelerek | 6G1,5 |

| Védettség | IP 68 |

| Szigetelőanyag osztály | F |

| Tekercstermosztát | igen |

| Csatlakozó | nincs |

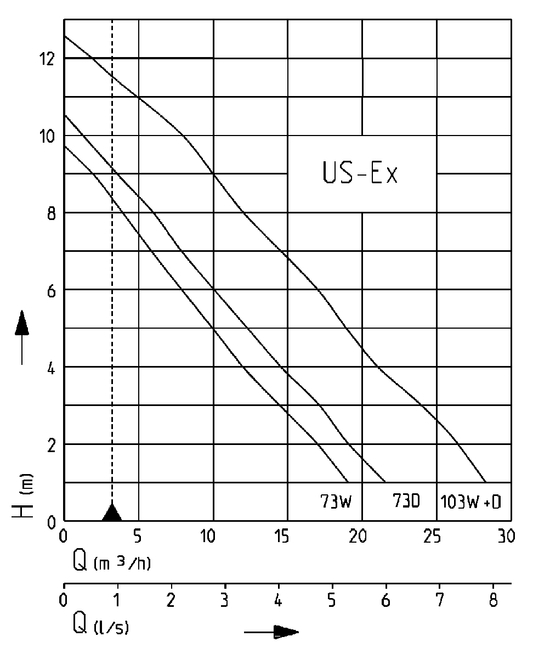

| Teljesítmény | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Szállítási magasság H [m] | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Szállítási mennyiség Q [m³/h] | 22 | 20 | 17 | 15 | 12 | 10 | 8 | 6 | 4 |

Konstrukciós változtatások joga fenntartva – Teljesítménytolerancia ISO 9906 szerint

Az EN12056 szabvány szerint a nyomócsőben a minimális áramlási sebességnek 0,7 m/s-nak kell lennie. A Q-H diagramon az alkalmazási határértékként (szaggatott vonal) látható.

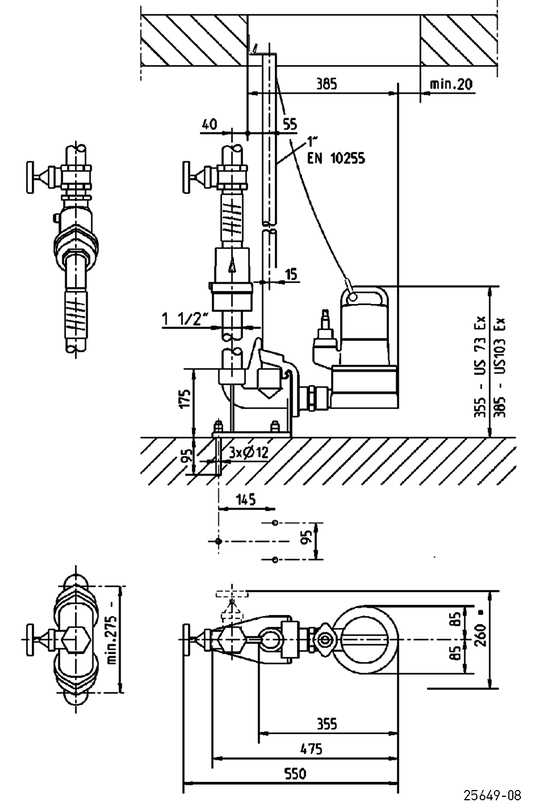

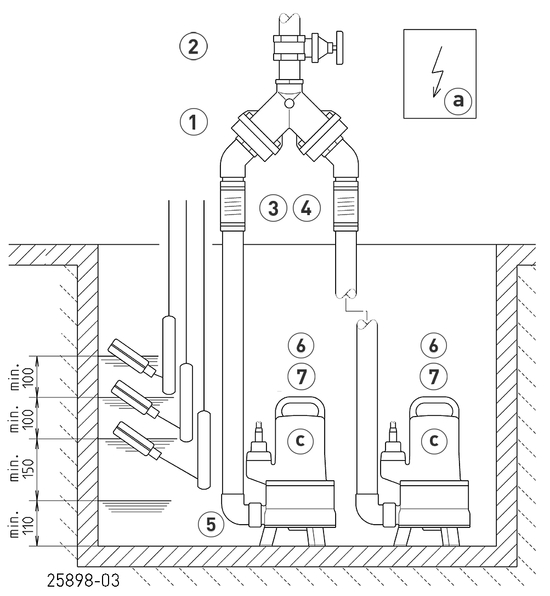

Mono elrendezés 1½" GR 40-nel: Akna min. 40x60 cm

Mono elrendezés1½" GR nélkül: Akna min. 40x40 cm

Duo elrendezés 1½" GR 40-nel: Akna min.60x60 cm

Duo elrendezés 1½" GR nélkül: Akna min. 40x60 cm

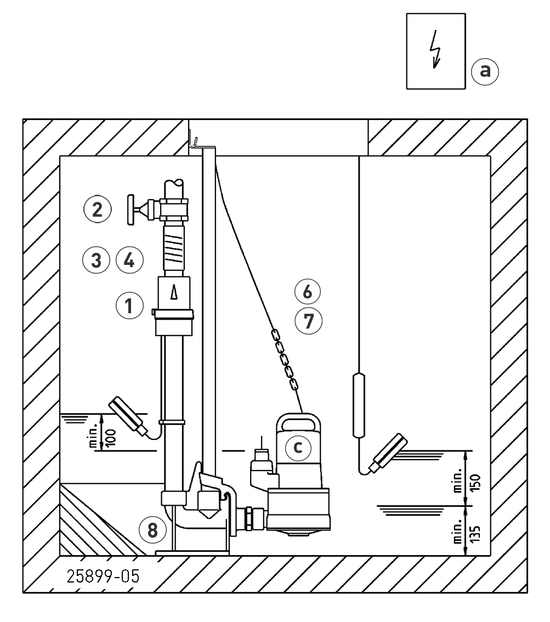

Az EN 12056 szabvány szerinti visszafolyási szint alatti használat esetén a nyomócsövet rugalmasan kell csatlakoztatni, és hurokkal kell vezetni a helyileg meghatározott visszatorlódási szint felett. Ezenkívül kötelező az EN 12050-4 szerint tesztelt visszacsapószelep felszerelése. A felügyelethez riasztórendszert is javasolunk.

Az EN 12056-4 szabvány 5.1. bekezdése szerint olyan rendszerekben, ahol a szennyvíz elvezetését nem szabad megszakítani, automatikus tartalékszivattyút vagy kettős rendszert kell beépíteni.

A vezérlőt száraz helyiségben kell felszerelni.

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Visszacsapószelep | ||||||

| R40 EN 12050-4 | 1½“ (DN 40), PN 4 | 150x120 (ma x szé) | JP00317 | |||

| DR 40 EN 12050-4 | 1½“ (DN 40), PN 4 | 200x280 (ma x szé) | JP09155 | |||

| Golyós visszacsapószelep | ||||||

| KE40 EN 12050-4 | 1½“ (DN 40), PN 6 | 170x125 (ma x szé) | JP47974 | |||

| Tolózár | ||||||

| Réz, 1½“ (DN 40), PN 16 | 125x60 (ma x szé) | JP44786 | ||||

| Elasztikus kötés | ||||||

| + Bilincs, 1½“ (DN 40), PN 4 | 120x50 (ma x mé) | JP50902 | ||||

| Könyök | ||||||

| 1½“ | JP45953 | |||||

| Lánc | ||||||

| tesztelt, 2,5 m, 320 kg, 5 függesztőkar (EN 818 mod.) | JP45901 | |||||

| tesztelt, 5,0 m, 320 kg, 8 függesztőkar (EN 818 mod.) | JP45902 | |||||

| Hordszíj | ||||||

| bilinccsel | JP45168 | |||||

| Vezetőcső rendszer | ||||||

| GR 40 | JP25592 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Vezérlő egyrendszerű berendezéshez | ||||||

| Vezérlő AD 23 X | az US 73D EX számára | JP09754 | ||||

| Vezérlő kettős rendszerű berendezéshez | ||||||

| Vezérlő BD 23 X | az US 73 D EX számára | JP09755 | ||||

| Szintjeladó | ||||||

| Búvárkapcsoló csomag AmG | 2 búvárkapcsoló 9,5 m súlyokkal | JP16719 | ||||

| Búvárkapcsoló csomag BmG | 3 búvárkapcsoló 9,5 m súlyokkal | JP16726 | ||||

| Segédkapcsoló készülék ExH-A | Rb szivattyúkhoz (egyes rendszerű berendezések) | JP16720 | ||||

| Segédkapcsoló készülék ExH-B | Rb szivattyúkhoz (kettős berendezések) | JP00295 | ||||

| Szintjeladó | ||||||

| Szárazmeneti védelem | JP44603 | |||||