compli 15100/2 B5 HL

JP50131| Mechanikai adatok | |

|---|---|

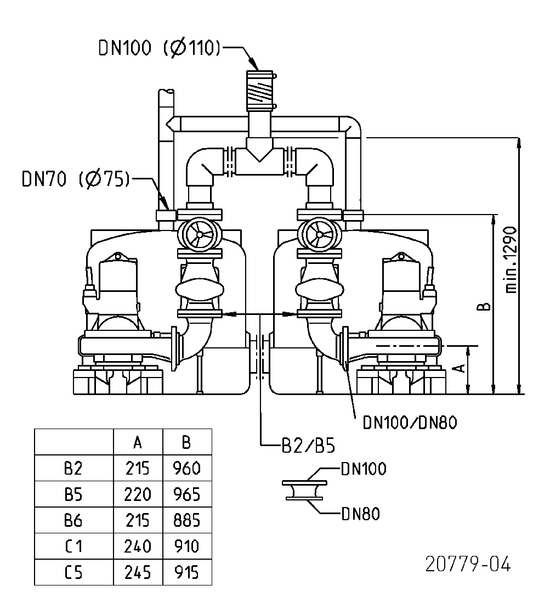

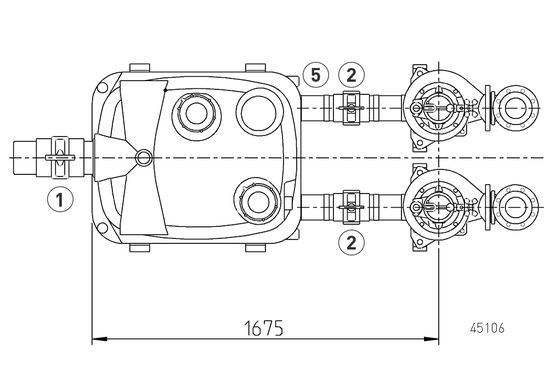

| Szivattyú | függőlegesen egyfokozatú |

| Szabad átmenet | 70 mm |

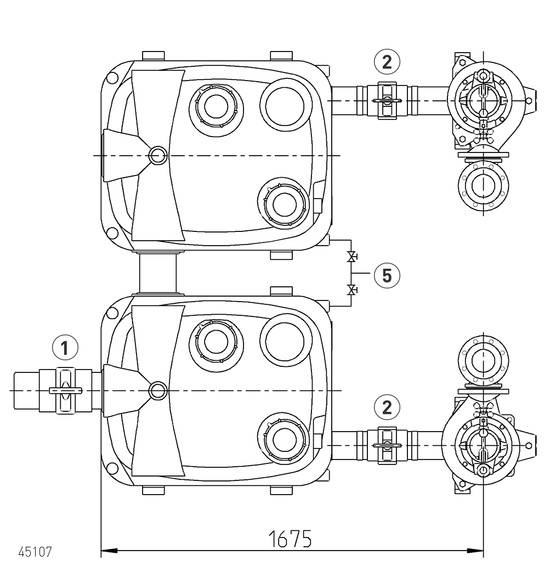

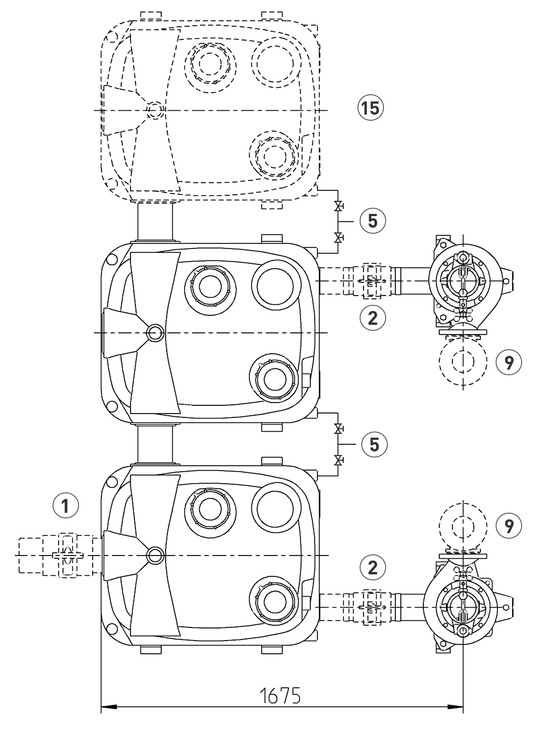

| Nyomóvezeték | DN 100 |

| Csapágy | Zsírkenésű golyóscsapágyak |

| Olajkamra | igen |

| Szárazmenetbiztos | igen |

| Járókerék | Csatornakerék, szürkeöntvény |

| Motorház | szürkeöntvény |

| Szivattyúház | szürkeöntvény |

| Elárasztható | igen |

| Nyomócsonk | DN 80 |

| Tartályvolumen | 500/1000 l |

| Súly | 368 kg |

| Villamos adatok | |

|---|---|

| Feszültség | 3/N/PE~400 V |

| Motorteljesítmény P1 | 10,5 kW |

| Motorteljesítmény P2 | 9,2 kW |

| Áram | 17,6 A 10,2 A |

| Hálózati vezeték | 10m H07RN-F |

| Kábelerek | 10G2,5 |

| Védettség | IP 68 |

| Szigetelőanyag osztály | F |

| Tekercstermosztát | igen |

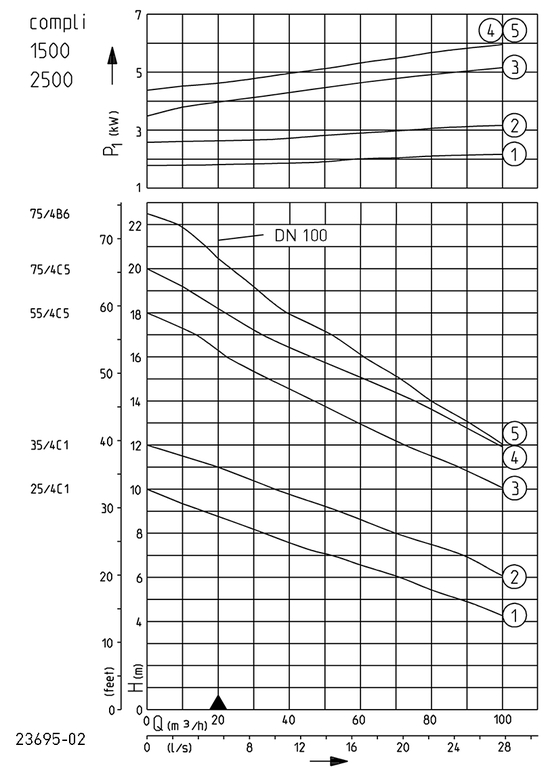

| Teljesítmény | |||||||

|---|---|---|---|---|---|---|---|

| Szállítási magasság H [m] | 22 | 25 | 28 | 31 | 34 | 37 | 40 |

| Szállítási mennyiség Q [m³/h] | 91 | 76 | 55 | 41 | 23 | 15 | 4 |

Konstrukciós változtatások joga fenntartva – Teljesítménytolerancia ISO 9906 szerint

Az EN12056 szabvány szerint a nyomócsőben a minimális áramlási sebességnek 0,7 m/s-nak kell lennie. A Q-H diagramon az alkalmazási határértékként (szaggatott vonal) látható.

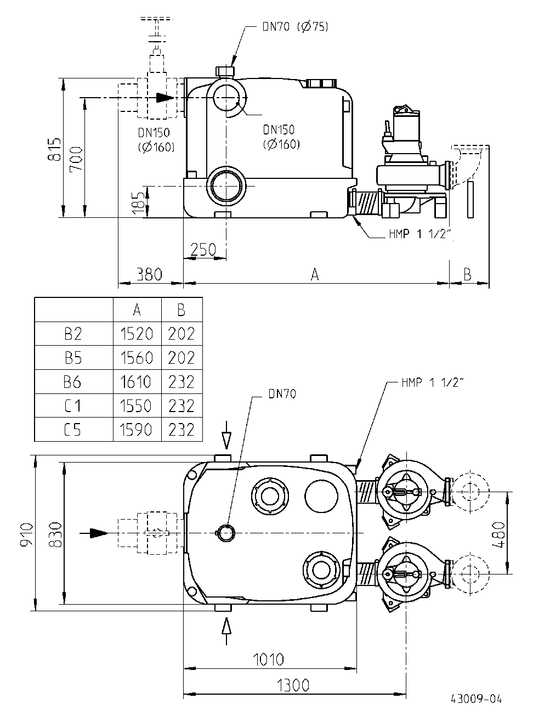

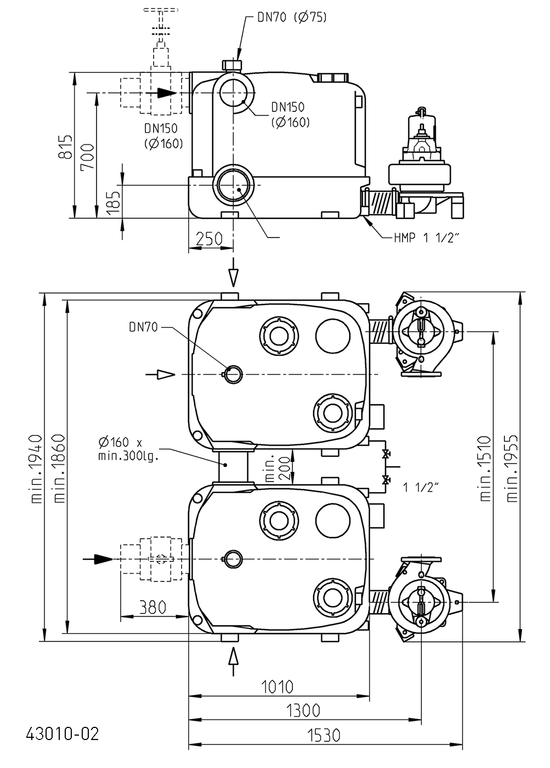

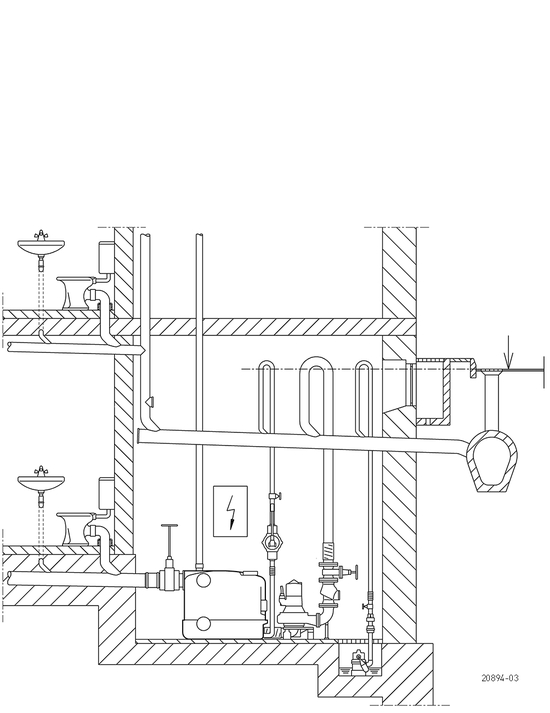

Az épületek vízelvezetésében fekáliát átemelő rendszereket kell alkalmazni az EN 12050 szabvány építési és vizsgálati elveinek megfelelően a széklet és a háztartási szennyvíz átszivattyúzására (EN 12056, DIN 1986-3). Ezeket az EN 12056-4 szabvány előírásai szerint kell beépíteni épületen belüli, 60 cm-es szabadon álló gyűjtőedénybe az üzemeltetéshez és karbantartáshoz. A nyomásvezetéket a helyileg meghatározott visszafolyási szint fölé kell emelni, és egy EN 12050-4 szerint tesztelt visszacsapószelepet kell felszerelni. A szellőzőcsövet a tető felett kell elvezetni.

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Bemeneti csúszka PVC | ||||||

| 2 csőcsonkkal, DN 150, PN 2,5 | 660x450 (ma x szé) | JP28591 | ||||

| Karbantartási tolattyú | ||||||

| 2 csőcsonkkal, DN 100, PN1, 300x295 (ma x szé) | JP45173 | |||||

| Lapos tolattyú ékkel | ||||||

| DN 100, PN 10, EN 1171 | 345x190 (ma x szé) | JP00329 | ||||

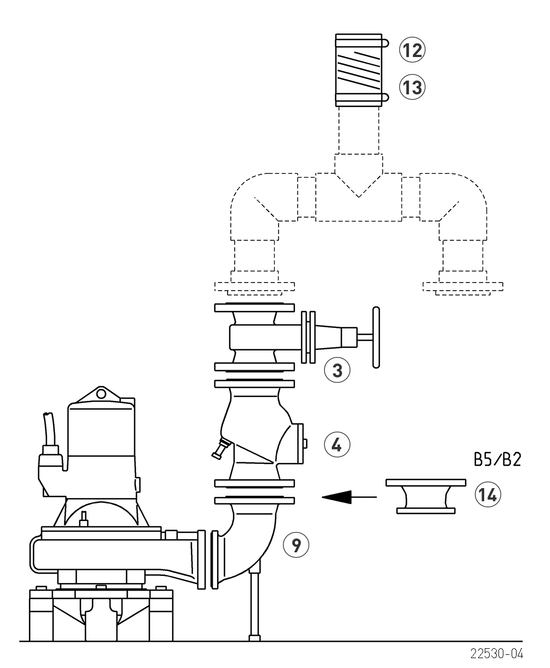

| Visszacsapószelep | ||||||

| R 101 EN 12050-4 | DN 100, PN 4, perem PN 10, EN 558, 300 (H) | JP00325 | ||||

| R 100 G EN 12050-4 | DN 100, PN 4, perem PN 10, EN 558, ellensúllyal, 300(H) | JP00324 | ||||

| Kézi membrános szivattyú | ||||||

| Sürgősségi ártalmatlanítás 15 m magasságig | 640x1½” (ma x mé) | JP00255 | ||||

| Tolózár | ||||||

| Réz, 1½“ (DN 40), PN 16 | 125x60 (ma x szé) | JP44786 | ||||

| Elasztikus kötés | ||||||

| + Bilincs, 1½“ (DN 40), PN 4 | 120x50 (ma x mé) | JP50902 | ||||

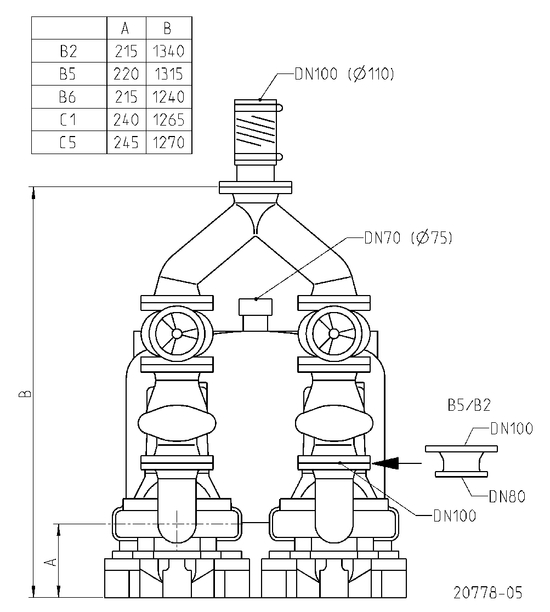

| Karimacsatlakoztatás | ||||||

| B 80 (hasonló Q-elem 90°), DN 80 PN10/PN6 | 150x100 (ma x szé) | JP00578 | ||||

| C 100 (hasonló Q-elem 90°), DN 100 PN10/PN6 | 175x120 (ma x szé) | JP00579 | ||||

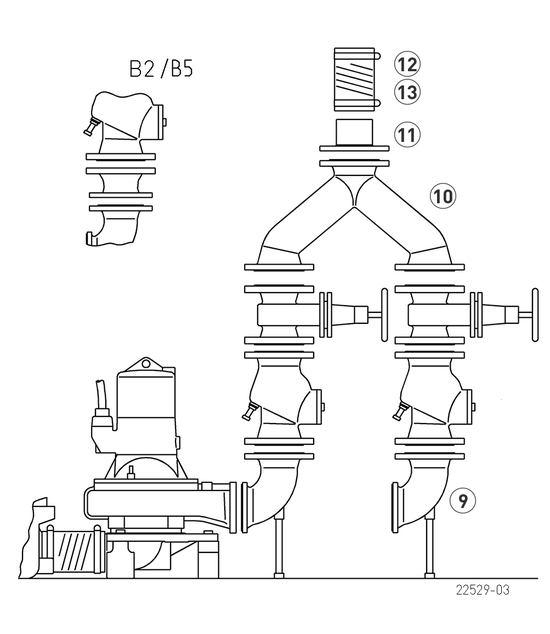

| Nadrágelem | ||||||

| DN 100/100/100 | 355x480(ma x szé), PN 10 | JP00203 | ||||

| Karimafelrakó elem | ||||||

| DN 100 PN 10, F-KS | 153x110 (ma x mé) | JP08673 | ||||

| DN 100 PN 10, F-idom | 100x114 (ma x mé) | JP00688 | ||||

| Elasztikus kötés | ||||||

| + Bilincs, 2“ DN 100, PN4 | 200x110 (ma x mé) | JP50905 | ||||

| + Bilincs, 2“ DN 100, PN4 | 200x114 (ma x mé) | JP50906 | ||||

| Átmeneti elem | ||||||

| DN 80/100 PN 10 szerint, (hasonló FFR-idom), H=100 | JP00498 | |||||

| Tartály | ||||||

| 500 l | JP45945 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Akkumulátor | ||||||

| 9 V, hálózatfüggetlen riasztáshoz | JP44850 | |||||

| Tömítettségellenőrzés | ||||||

| DKG szonda olajkamra ellenőrzéshez | JP44900 | |||||

| Smart Home | ||||||

| FTJP rádióadó az EnOcean protokollhoz | JP47209 | |||||