MultiStream 230/4 C6

JP09885| Mechanikai adatok | |

|---|---|

| Szivattyú | függőlegesen egyfokozatú |

| Szabad átmenet | 100 mm |

| Csapágy | Zsírkenésű golyóscsapágyak |

| Motoroldali tömítés | 2-szeres tengelytömítő gyűrű, 55-től/: Csúszógyűrű tömítés |

| Olajkamra | igen |

| Közegoldali tömítés | SiC csúszógyűrűs tömítés |

| Szárazmenetbiztos | igen |

| Járókerék | Csatornakerék, szürkeöntvény, 55/2...-től Lágyvas |

| Motorház | szürkeöntvény |

| Szivattyúház | szürkeöntvény |

| Elárasztható | igen |

| Nyomócsonk | DN 100 |

| Súly | 275 kg |

| Villamos adatok | |

|---|---|

| Feszültség | 3/PE~400/690 V |

| Motorteljesítmény P1 | 19,3 kW |

| Motorteljesítmény P2 | 17 kW |

| Áram | 34,1 A 19,8 A |

| Hálózati vezeték | 10m H07RN-F |

| Kábelerek | 10G2,5 |

| Védettség | IP 68 |

| Készülékbiztosítás | 35 A |

| S3 | 35 % |

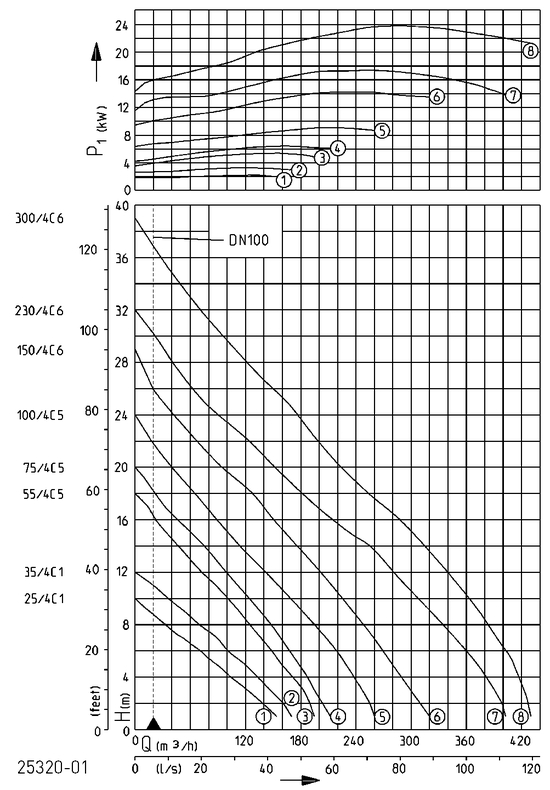

| Teljesítmény | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Szállítási magasság H [m] | 1 | 3 | 5 | 7 | 9 | 12 | 14 | 16 | 18 | 20 | 23 | 24 | 26 | 27 | 28 | 29 | 30 | 31 |

| Szállítási mennyiség Q [m³/h] | 405 | 390 | 372 | 344 | 320 | 283 | 255 | 218 | 182 | 155 | 110 | 91 | 62 | 51 | 40 | 32 | 22 | 8 |

Konstrukciós változtatások joga fenntartva – Teljesítménytolerancia ISO 9906 szerint

A v = 0,7 m/s minimális áramlási sebesség a nyomóvezetékben (nyomászárás) alkalmazási határértékként látható a Q-H diagramon.

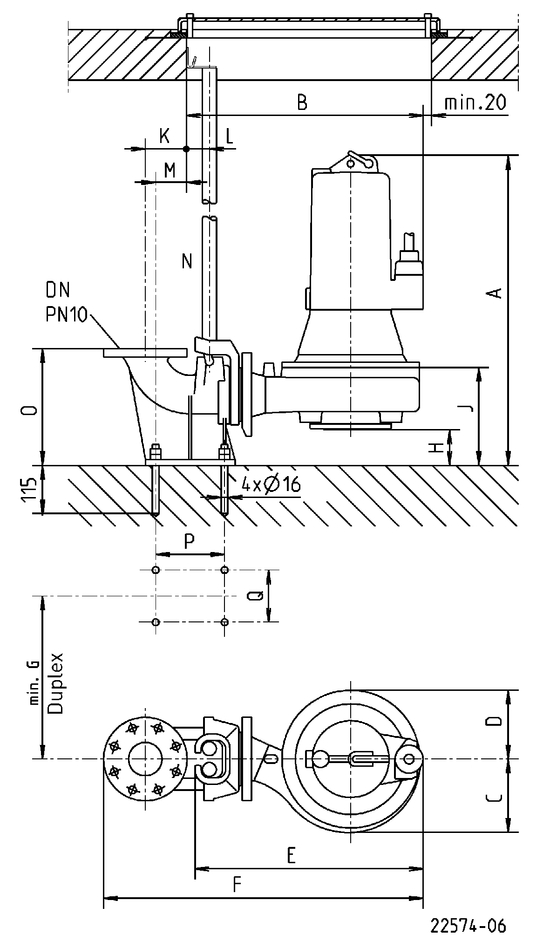

Csúszócső rendszer beépítési méretei

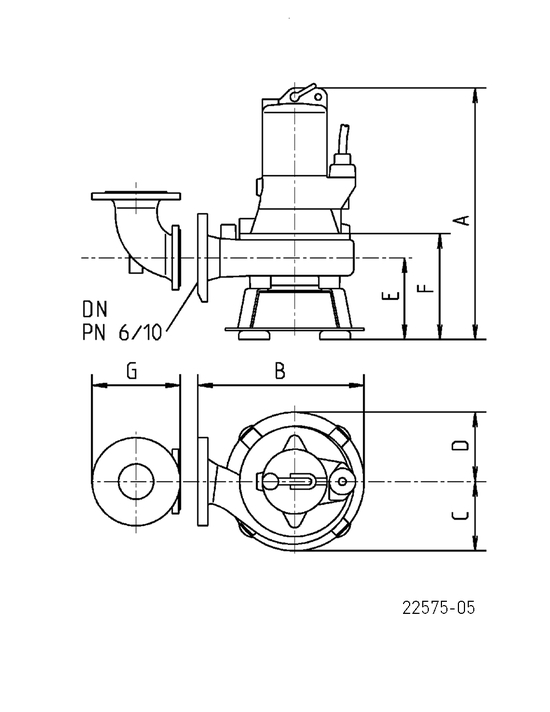

A támaszláb beépítési méretei

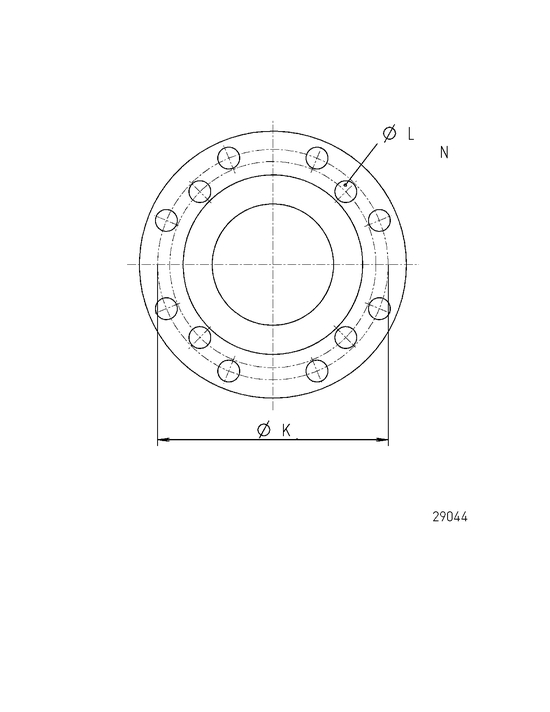

Szivattyú nyomáskimenet

| A csúszócső beépítési méretei | |

|---|---|

| GR | 101 |

| DN | 100 |

| A | 1000 mm |

| B | 755 mm |

| C | 290 mm |

| D | 250 mm |

| E | 735 mm |

| F | 975 mm |

| G | 580 mm |

| H | 105 mm |

| J | 315 mm |

| K | 110 mm |

| L | 55 mm |

| M | 82 mm |

| N | 1" |

| O | 345 mm |

| P | 175 mm |

| Q | 385 mm |

| A tartóláb beépítési méretei | |

|---|---|

| DN | 100 |

| A | 1015 mm |

| B | 610 mm |

| C | 290 mm |

| D | 250 mm |

| E | 250 mm |

| F | 330 mm |

| G | 230 mm |

| K | 170 mm |

| L | 18 mm |

| N | 4 |

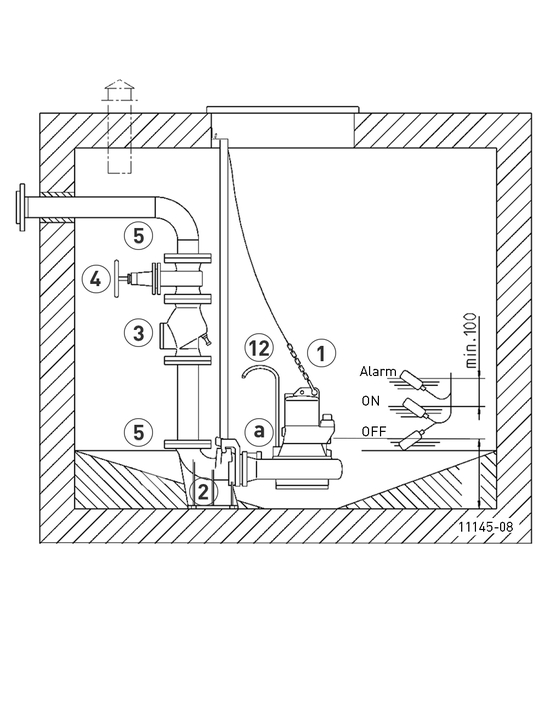

Beépítési példa csúszócsöves rendszerre

A szükséges tartozékokat és kiegészítő felszereléseket lásd a kezelőszerveknél

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Lánc | ||||||

| tesztelt, 2,5 m, 320 kg, 5 függesztőkar (EN 818 mod.) | JP45901 | |||||

| tesztelt, 5,0 m, 320 kg, 8 függesztőkar (EN 818 mod.) | JP45902 | |||||

| tesztelt, 7,5 m, 320 kg, 11 függesztőkar (EN 818 mod.) | JP47365 | |||||

| Bilincs, tesztelt, 630 kg, rozsdamentes acél | JP45904 | |||||

| Vezetőcső rendszer | ||||||

| GR 101 | DN 100, 235x254x345 (ho x szé x ma) | JP21037 | ||||

| Visszacsapószelep | ||||||

| R 101 EN 12050-4 | DN 100, PN 4, perem PN 10, EN 558, 300 (H) | JP00325 | ||||

| R 100 G EN 12050-4 | DN 100, PN 4, perem PN 10, EN 558, ellensúllyal, 300(H) | JP00324 | ||||

| Lapos tolattyú ékkel | ||||||

| DN 100, PN 10, EN 1171 | 345x190 (ma x szé) | JP00329 | ||||

| Karimafelrakó elem | ||||||

| DN 100 PN 10, F-KS | 153x110 (ma x mé) | JP08673 | ||||

| DN 100 PN 10, F-idom | 100x114 (ma x mé) | JP00688 | ||||

| Elasztikus kötés | ||||||

| + Bilincs, 2“ DN 100, PN4 | 200x110 (ma x mé) | JP50905 | ||||

| + Bilincs, 2“ DN 100, PN4 | 200x114 (ma x mé) | JP50906 | ||||

| Támaszláb | ||||||

| C 410, a C3,C4,C6,C7 számára | 145x650 (ma x szé) | JP00702 | ||||

| Karimacsatlakoztatás | ||||||

| C 100 (hasonló Q-elem 90°), DN 100 PN10/PN6 | 175x120 (ma x szé) | JP00579 | ||||

| Öblítőcső | ||||||

| Típus III | 150/... - 300/... | JP28223 | ||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Tömítettségellenőrzés | ||||||

| DKG szonda olajkamra ellenőrzéshez | JP44900 | |||||