UV 315-1

JP48699| Mechanical data | |

|---|---|

| Pump | Vertical single-stage |

| Free passage | 10 mm |

| Bearing | Ball bearings, grease-lubricated |

| Seal on motor side | Mechanical seal |

| Oil chamber | Yes |

| Seal on medium side | SiC mechanical seal |

| Run dry protection | Yes |

| Shaft | Stainless steel |

| Impeller | Stainless steel |

| Motor housing | Stainless steel |

| Submersible | Yes |

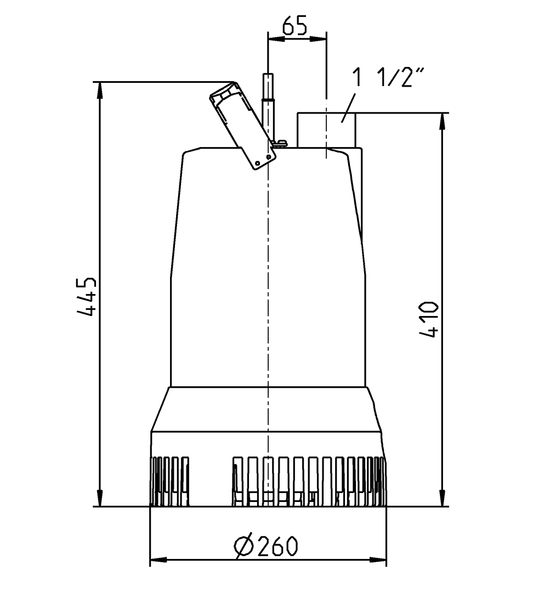

| Pressure outlet | IG 1 1/2" |

| Weight | 19 kg |

| Electrical data | |

|---|---|

| Ciruit | Without level control |

| Voltage | 1/N/PE~230 V |

| Motor rating P1 | 1.83 kW |

| Motor rating P2 | 1.36 kW |

| Current | 8.2 A |

| Power line | 10m H07RN8-F |

| Wires | 3G1,0 |

| Type of enclosure | IP 68 |

| Insulation class | F |

| Winding thermostat | Yes |

| Motor protection | Integrated |

| Plug | Safety |

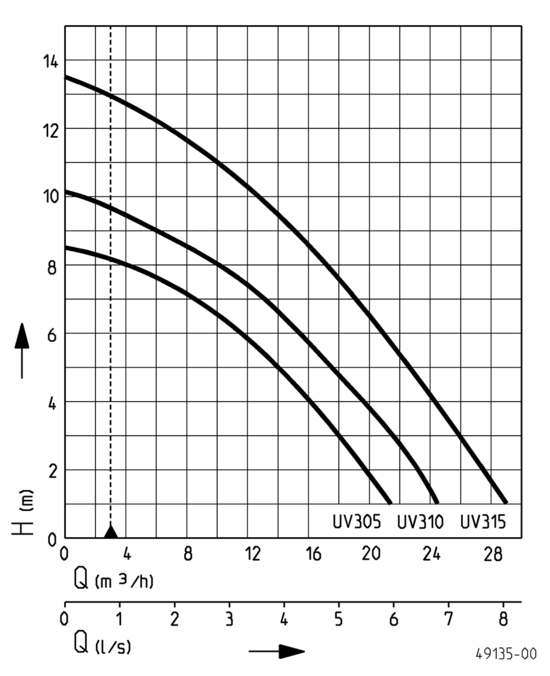

| Performance | |||||||

|---|---|---|---|---|---|---|---|

| Delivery head H [m] | 1 | 3 | 5 | 7 | 9 | 11 | 13 |

| Flow rate Q [m³/h] | 28 | 25 | 22 | 19 | 14.5 | 10 | 2 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

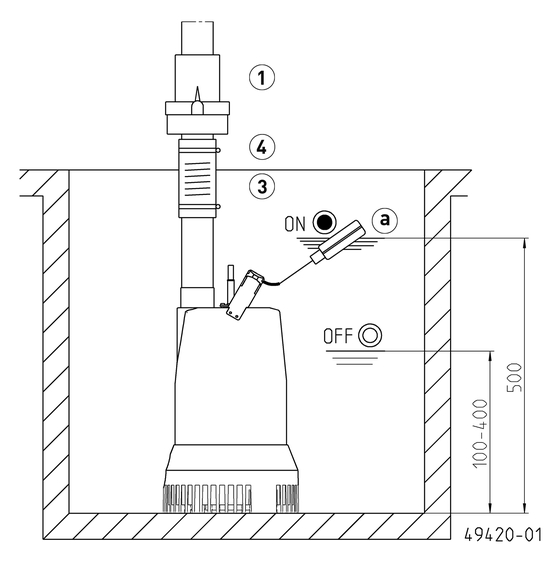

Single unit: sump area 40x50 cm

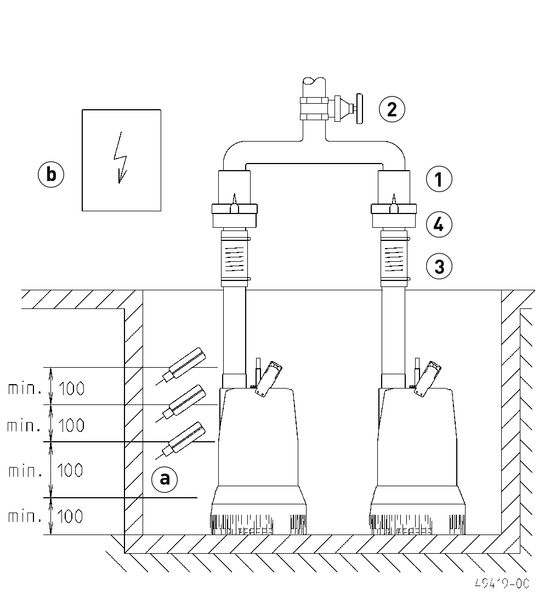

Duplex unit: sump min. 40x70 cm

In case of installation beneath the backpressure level the pressure tube must be taken in a loop over the local backup level acc. to EN 12056. Besides, it must be secured with an EN 12050-4-proofed swing-type check valve. Additionally we recommend an alarm system.

In accordance with EN 12056-4 section 5.1, it has a built-in automatic spare pump or a double attachment included, which ensures that sewage drainage is not interrupted.

Suspend control unit in a dry room

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Swing-type check valve | ||||||

| R40 EN 12050-4 | 1½“ (DN 40), PN 4 | 150x120 (HxB) | JP00317 | |||

| DR 40 EN 12050-4 | 1½“ (DN 40), PN 4 | 200x280 (HxB) | JP09155 | |||

| Stop valve | ||||||

| brass, 1½“ (DN 40), PN 16 | 125x60 (HxB) | JP44786 | ||||

| Elastic connection | ||||||

| + Hose band clamps, 1½“ (DN 40), PN 4 | 120x50 (HxD) | JP50902 | ||||

| Hose coupling | ||||||

| Coupling Storz C | 1½“ male thread | JP44770 | ||||

| Coupling wrench | JP25708 | |||||

| Pressure hose | ||||||

| 12,5 m, synthetic, with coupling Storz C, Ø 38 mm | JP50298 | |||||

| 15 m, synthetic, with coupling Storz C, Ø 52 mm | JP00336 | |||||

| Chain | ||||||

| certified, 2.5 m, 320 kg, 5 rings (EN 818 mod.) | JP45901 | |||||

| certified, 5.0 m, 320 kg, 8 rings (EN 818 mod.) | JP45902 | |||||

| certified, 7.5 m, 320 kg, 11 rings (EN 818 mod.) | JP47365 | |||||

| Shackle, certified, 630 kg, stainless steel | JP45904 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Alarm unit | ||||||

| AG10 | subm. ball contact switch, mains dependent, potential-free contact, 9.5 m cable | JP44892 | ||||

| Control for single units | ||||||

| Control unit HIGHLOGO 1-00 E | 230 V | JP47987 | ||||

| Control unit AD 00 E | 230 V | JP00289 | ||||

| Control for duplex units | ||||||

| Control unit HIGHLOGO 2-00 E | 230 V | JP47996 | ||||

| Control unit BD 00 E | 230 V, for pumps U3-U6, US 62-105, UV3, UV 300, 08/2 ME | JP45735 | ||||

| Level control | ||||||

| Subm. switch pack A | 2 subm. ball contact switches 9.5 m and fixing devices | JP16718 | ||||

| Subm. switch pack AmG | 2 subm. ball contact switch with 9.5 m and counterweight | JP16719 | ||||

| Subm. switch pack B | 3 subm. ball contact switch with 9.5 m and fixing devices | JP16725 | ||||

| Subm. switch pack BmG | 3 subm. ball contact switch with 9.5 m and counterweight | JP16726 | ||||

| Rechargeable battery | ||||||

| 9 V, for mains independent alarm | JP44850 | |||||