Submersible drainage pumps

US 62–US 251

Submersible pumps for commercial applications

Areas of application: Heavily contaminated and abrasive waste and drainage water

Made in Germany

- 10 mm free passage

- Safe to run dry

- Controllable oil chamber

- SiC mechanical seal independent of sense of rotation

- Replaceable moisture sealed cable inlet

The centrifugal submersible drainage pumps US 62-251 can be used wherever sewage water with solids up to 10 mm particle size occurs, e.g. in collecting sumps for ground water, or in permanent draining systems for clean water, or handling solids in suspension. They are also ideal for pumping the sewage water from collecting sumps into which dishwashers or washing machines are discharging. For high temperature hot water in the industrial and commercial field we recommend the use of our US 73 and US 103 HE/HES.

This range of pumps is suitable for stationary and portable use. For easy removal of the pumps from deep sumps we recommend the use of our guide rail systems which provide ease of maintenance and inspection.

For automatic monitoring of the oil chamber a seal leak control can be connected.

Maximum cable length of the pumps is 10 m. 3-phase pumps with level control (US 151 DS, US 152 DS and US 251 DS) have a CEE-Plug with phase inverter.

The sewage pumps are tested by the German Institute for Construction Engineering and correspond to the valid construction and test principles.

Pump according to DIN EN 12050 ready for connection with 10 m cable. US 62 and US 102 with safety plug (1-phase) or CEE-Plug (3-phase).

US 151, US 152 and 251: Pumps without level control with free lead end. Pump with built-in level control with CEE-Plug and phase inverter (3-phase) or safety-plug (1-phase).

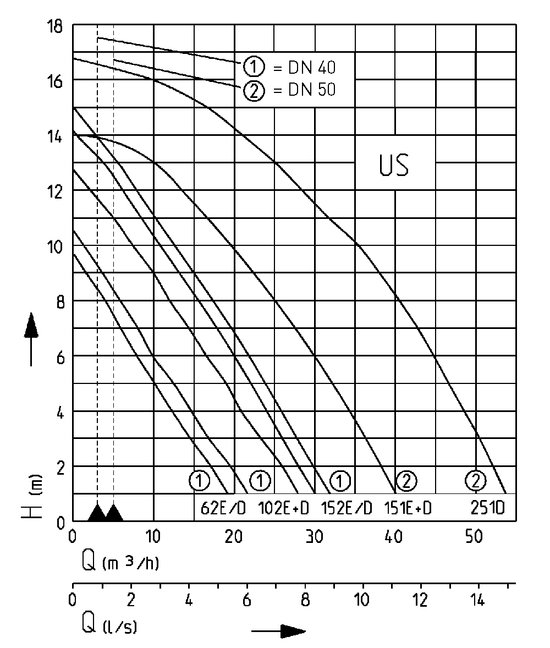

| Delivery head Hmax | 16 m |

| Flow rate Qmax | 54 m³/h |

| Free passage | 10 mm |

| Pressure outlet | IG 1 1/2" IG 2" |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

VDE/GS-Certification for US 62 E/ES, US 102 E/ES

18 results

| Type | Code No. | Ciruit | Voltage | Motor rating P1 | Motor rating P2 | Current | Motor protection | Plug |

|---|---|---|---|---|---|---|---|---|

JP09812 | Without level control | 1/N/PE~230 V | 0.83 kW | 0.5 kW | 3.9 A | Integrated | Safety | |

JP09813 | Without level control | 3/PE~400 V | 0.85 kW | 0.6 kW | 1.4 A | Integrated | CEE | |

JP09278 | Without level control | 1/N/PE~230 V | 1.37 kW | 0.98 kW | 6 A | Integrated | Safety | |

JP00214 | Without level control | 3/PE~400 V | 1.36 kW | 1.06 kW | 2.4 A | Integrated | CEE | |

JP09435 | Without level control | 1/N/PE~230 V | 1.6 kW | 1.21 kW | 7.5 A | on request | Without | |

JP09437 | Without level control | 3/PE~400 V | 1.7 kW | 1.41 kW | 3.1 A | on request | Without | |

JP09814 | With built-in level control | 1/N/PE~230 V | 0.83 kW | 0.5 kW | 3.9 A | Integrated | Safety | |

JP09815 | With built-in level control | 3/PE~400 V | 0.85 kW | 0.6 kW | 1.4 A | Integrated | CEE | |

JP09279 | With built-in level control | 1/N/PE~230 V | 1.37 kW | 0.98 kW | 6 A | Integrated | Safety | |

JP00218 | With built-in level control | 3/PE~400 V | 1.36 kW | 1.06 kW | 2.4 A | Integrated | CEE | |

JP09436 | With built-in level control | 1/N/PE~230 V | 1.6 kW | 1.21 kW | 7.5 A | Integrated | Safety | |

JP09438 | With built-in level control | 3/PE~400 V | 1.7 kW | 1.41 kW | 3.1 A | Integrated | CEE | |

JP09310 | Without level control | 1/N/PE~230 V | 1.68 kW | 1.19 kW | 7.6 A | on request | Without | |

JP09300 | Without level control | 3/N/PE~400 V | 1.6 kW | 1.3 kW | 3 A | on request | Without | |

JP09301 | Without level control | 3/N/PE~400 V | 2.6 kW | 2.1 kW | 4.4 A | on request | Without | |

JP09241 | With built-in level control | 1/N/PE~230 V | 1.68 kW | 1.19 kW | 7.6 A | Integrated | Safety | |

JP09243 | With built-in level control | 3/N/PE~400 V | 1.6 kW | 1.3 kW | 3 A | Integrated | CEE | |

JP09245 | With built-in level control | 3/N/PE~400 V | 2.6 kW | 2.1 kW | 4.4 A | Integrated | CEE |