MultiFree 15/4 CW1

JP09612| Mechanical data | |

|---|---|

| Pump | Vertical single-stage |

| Free passage | 100 mm |

| Bearing | Ball bearings, grease-lubricated |

| Seal on motor side | Duplex shaft seal, from 55/: mechanical seal |

| Oil chamber | Yes |

| Seal on medium side | SiC mechanical seal |

| Run dry protection | Yes |

| Impeller | Vortex impeller, spheroidal graphite iron |

| Motor housing | Grey cast iron |

| Pump housing | Grey cast iron |

| Submersible | Yes |

| Pressure outlet | DN 100 |

| Weight | 49 kg |

| Electrical data | |

|---|---|

| Voltage | 3/PE~400 V |

| Motor rating P1 | 2.4 kW |

| Motor rating P2 | 1.9 kW |

| Current | 4.4 A |

| Power line | 10m H07RN-F |

| Wires | 6G1,5 |

| Type of enclosure | IP 68 |

| Winding thermostat | Yes |

| Fuse | 10 A |

| S3 | 30 % |

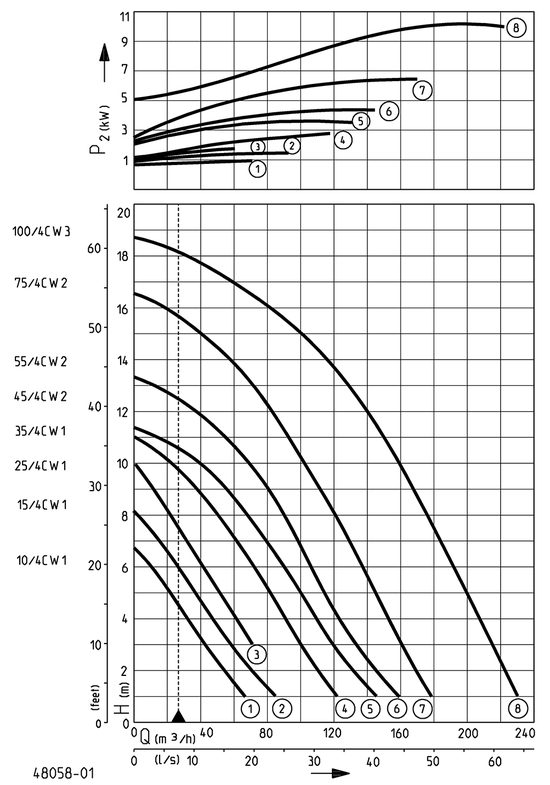

| Performance | ||||||||

|---|---|---|---|---|---|---|---|---|

| Delivery head H [m] | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Flow rate Q [m³/h] | 85 | 69 | 56 | 46 | 37 | 28 | 18 | 5 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow rate in the pressure pipe of v = 0,7 m/s is marked in the Q-H-diagram (operative limit).

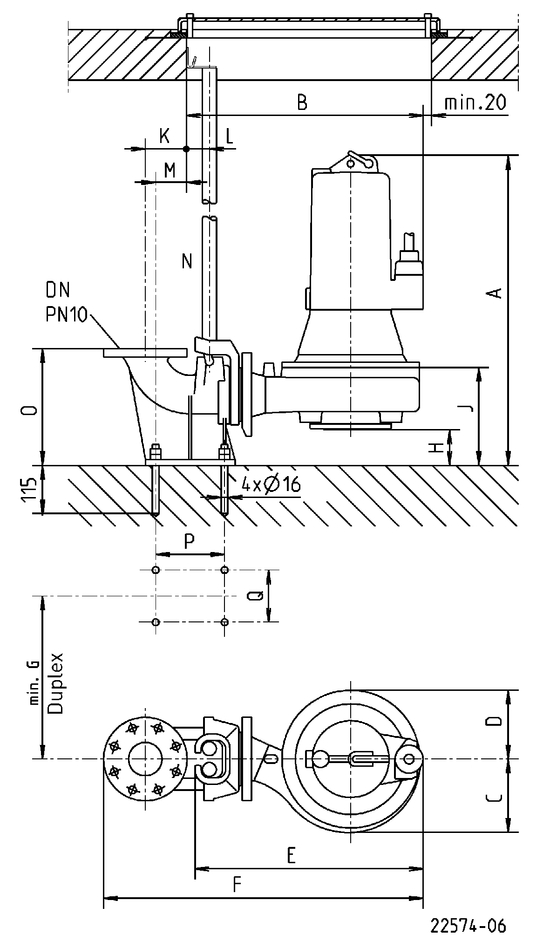

Dimensions guide rail system

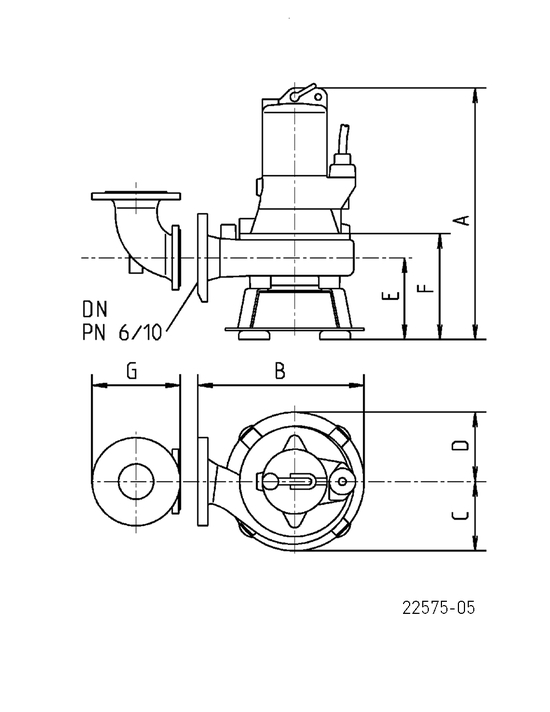

Dimensions pump base

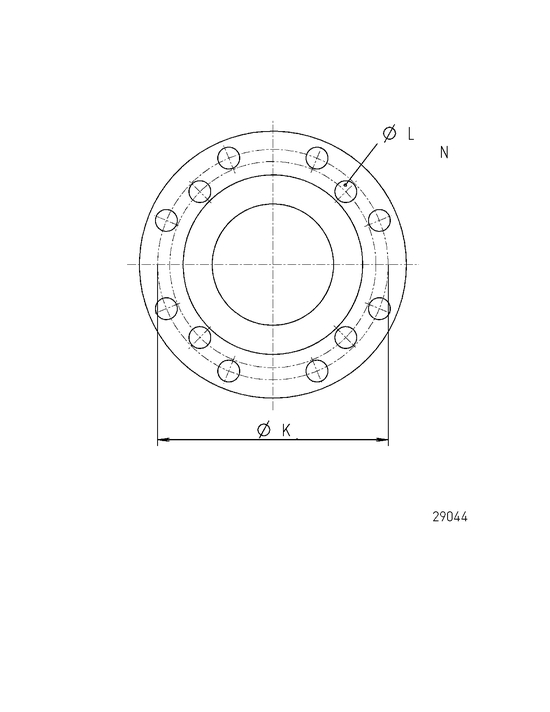

Discharge outlet

Minimum flushing tube head (m)

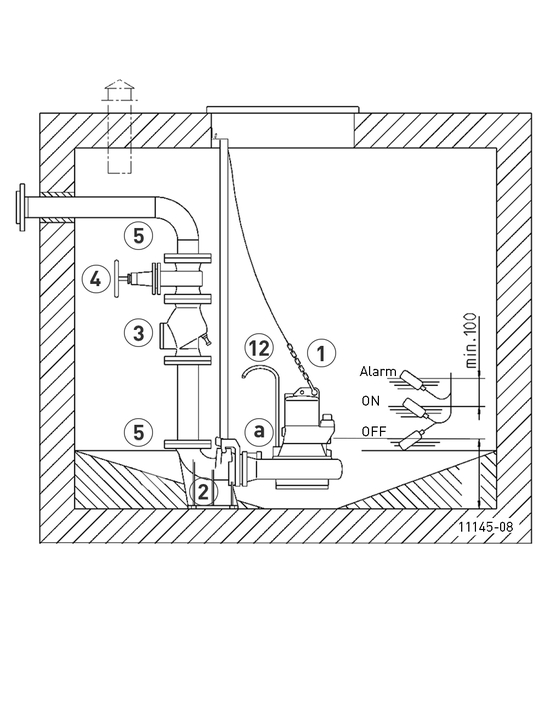

| Mounting arrangement with guide rail system | |

|---|---|

| GR | 100 |

| DN | 100 |

| A | 565 mm |

| B | 540 mm |

| C | 140 mm |

| D | 140 mm |

| E | 520 mm |

| F | 760 mm |

| G | 390 mm |

| H | 120 mm |

| J | 270 mm |

| K | 110 mm |

| L | 55 mm |

| M | 82 mm |

| N | 1" |

| O | 310 mm |

| P | 175 mm |

| Q | 150 mm |

| Mounting arrangement with base | |

|---|---|

| DN | 100 |

| A | 590 mm |

| B | 390 mm |

| C | 140 mm |

| D | 140 mm |

| E | 220 mm |

| F | 290 mm |

| G | 230 mm |

| K | 170 mm |

| L | 18 mm |

| N | 4 |

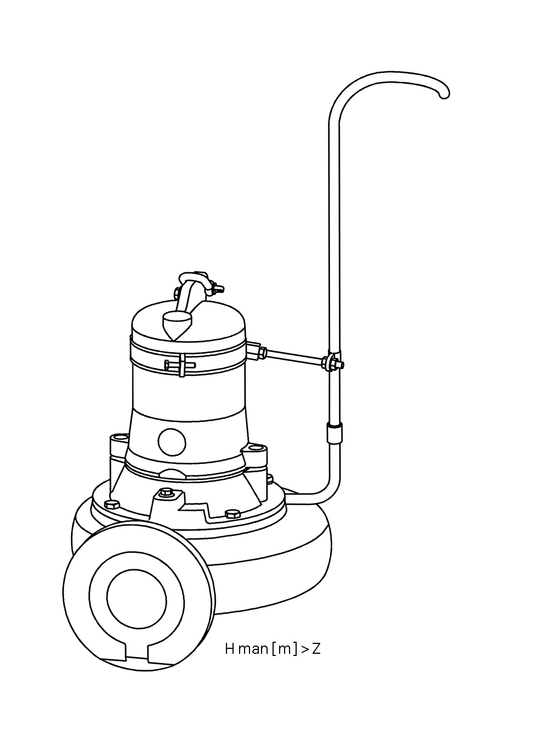

| Z [m] | 4 mm |

Example of installation guide rail system

Additional requirements, see technical data control units

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Chain | ||||||

| certified, 2.5 m, 320 kg, 5 rings (EN 818 mod.) | JP45901 | |||||

| certified, 5.0 m, 320 kg, 8 rings (EN 818 mod.) | JP45902 | |||||

| certified, 7.5 m, 320 kg, 11 rings (EN 818 mod.) | JP47365 | |||||

| Shackle, certified, 630 kg, stainless steel | JP45904 | |||||

| Pump hanging (08 Ex - 100...) | JP45925 | |||||

| Guide rail system | ||||||

| GR 100 | DN 100, 200x254x310 (AxBxH) | JP00496 | ||||

| Swing-type check valve | ||||||

| R 101 EN 12050-4 | DN 100, PN 4, flange PN 10, EN 558, 300 (H) | JP00325 | ||||

| R 100 G EN 12050-4 | DN 100, PN 4, flange PN 10, EN 558, with counter weight, 300(H) | JP00324 | ||||

| Sluice valve | ||||||

| DN 100, PN 10, EN 1171 | 345x190 (HxB) | JP00329 | ||||

| Flanged spigot | ||||||

| DN 100 PN 10, F-KS | 153x110 (HxD) | JP08673 | ||||

| DN 100 PN 10, F-piece | 100x114 (HxD) | JP00688 | ||||

| Elastic connection | ||||||

| + Clamps, 2“ DN 100, PN 4 | 200x110 (HxD) | JP50905 | ||||

| + Clamps ,2“ DN 100, PN 4 | 200x114 (HxD) | JP50906 | ||||

| Flanged Y-pipe | ||||||

| DN 100/100/100 | 355x480(HxB), PN 10 | JP00203 | ||||

| Pump base | ||||||

| C 220, for CW1 | 145x330 (HxB) | JP11453 | ||||

| Flanged connection | ||||||

| C 100 (similar Q-piece 90°), DN 100 PN10/PN6 | 175x120 (HxB) | JP00579 | ||||

| Flushing tube | ||||||

| Type I | 10/... - 45/... | JP28221 | ||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Seal leak detector | ||||||

| DKG (für die Ölkammer) | JP44900 | |||||