Sewage lifting stations with MultiCut cutting system

Compli MC

Sewage lifting station with MultiCut series cutter pumps

Perfect for long and small dimensioned pressure lines

Areas of application: Campsites, toilet trailers, etc.

5-year warranty for specialist tradesmen when registered

at www.hauptsachejung.de/en

Made in Germany

- Ready to connect

- Submersible

- Clamp-type inlet flange

- Versatile connection facilities

- Small dimensioned pressure pipe

- High delivery head

- PE-tank

- Multicut cutting system

The sewage lifting stations Compli 100, Compli 500 and Compli 1000 with MultiCut cutting system are uses especially for disposal in special objects, such as weekend cottages, houseboats, toilets in production halls or mobile sanitary facilities.

The MultiCut cutting system enables wastewater to be pumped through long and small-dimensioned pressure pipes to the nearest sewer whereby the pressure pipes can follow the terrain. This type of wastewater transport is more economical in many cases than disposal by gravity sewer. The external cutting system ensures safe operation.

The submergible units are permitted for general use in areas subject to flooding. The control unit has to be fitted in a well ventilated flood-proof room. The PE tanks have freely accessible drains, a top-mounted cleaning opening and a clamp-type inlet flange for an easy installation. The inlet height is variable depending on the type and inlet pipe:

Compli 100: DN 50: 150, 250 mm; DN 150/DN 50: 180, 275 a.315 mm

Compli 500/1000: DN 100:180, 250 mm; DN 100: 180-340 mm.

For the connection of an inlet pipe DN 100 a PVC reducer DN 150/DN 100 is added to the Compli 500 and 1000. A vertical inlet neck is mounted on top of the tank for an inlet pipe DN 150 or DN 100. If the rear inlet is not used it must be closed with the sealing set DN 150 (accessory). The duplex units Compli 1000 have two pumps, that operate alternately. In case of peak load operation both pumps operate at the same time.

Ready-to-connect tank system (capacity 38 l respectively 115 l) in keeping with German / European standard 12050 with height-adjustable DN 100 revolver clamping flange for inlet height 180/250 mm for Compli 100; Compli 500 and 1000 PVC-tube DN 150 (180, 275, 315 mm), DN 100 (180-340 mm), additional horizontal and vertical inlets, diam. 50 mm, adapter DN 150/DN 100, pre-mounted submersible pump, one elastic connection each with clamps for plastic pressure pipes and jointing tube for DN 70 ventilation pipe, mounted non-return valve, automatic float switch circuit, control (IP 44 type of protection) with motor protection, contactor, transformer, mains-dependable optionally acknowledgeable alarm system and potential-free contact for collective failure messages, optical display of sense of direction (three-phase current), alarm and operation, button for test run. Single units with adjustable maintenance interval display and input for additional high water alarm

Cable between tank and control 4 m, cable between control and plug 1.5 m.

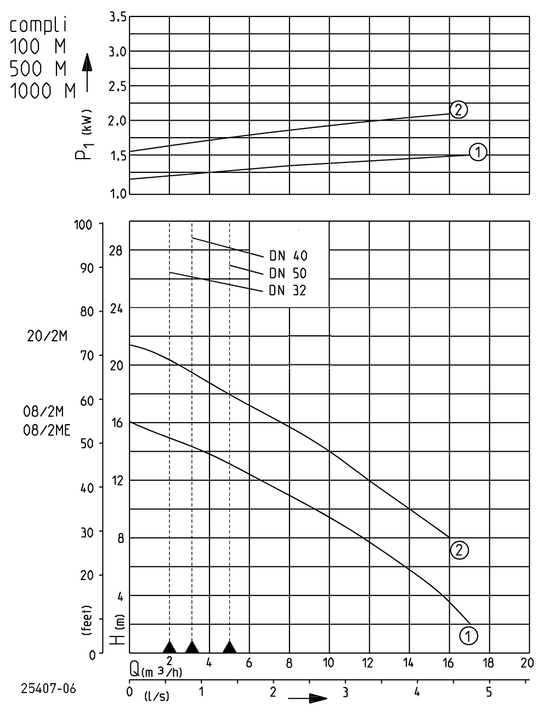

| Delivery head Hmax | 21 m |

| Flow rate Qmax | 17 m³/h |

| Free passage | 7 mm |

| Pressure outlet | DN 40 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

9 results

| Type | Code No. | Voltage | Motor rating P1 | Motor rating P2 | Current | Plug | Pressure pipe | Pressure outlet | Tank capacity |

|---|---|---|---|---|---|---|---|---|---|

JP50088 | 1/N/PE~230 V | 1.7 kW | 1.14 kW | 7.5 A | Safety | DN 32 | DN 32 | 38 l | |

JP50089 | 3/N/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | CEE | DN 32 | DN 32 | 38 l | |

JP50090 | 3/N/PE~400 V | 2.3 kW | 1.85 kW | 3.9 A | CEE | DN 32 | DN 32 | 38 l | |

JP50096 | 1/N/PE~230 V | 1.7 kW | 1.14 kW | 7.5 A | Safety | DN 40 | DN 40 | 117 l | |

JP50097 | 3/N/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | CEE | DN 40 | DN 40 | 117 l | |

JP50098 | 3/N/PE~400 V | 2.3 kW | 1.85 kW | 3.9 A | CEE | DN 40 | DN 40 | 117 l | |

JP50112 | 1/N/PE~230 V | 1.7 kW | 1.14 kW | 7.5 A | Safety | DN 40 | DN 40 | 117 l | |

JP50114 | 3/N/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | CEE | DN 40 | DN 40 | 117 l | |

JP50115 | 3/N/PE~400 V | 2.3 kW | 1.85 kW | 3.9 A | CEE | DN 40 | DN 40 | 117 l |