Pressure drainage

In urbanised residential areas with flat or hilly terrain, high groundwater levels or adverse soil conditions, the pressure drainage method has proven itself for years as an economical and efficient solution.

The functional principle

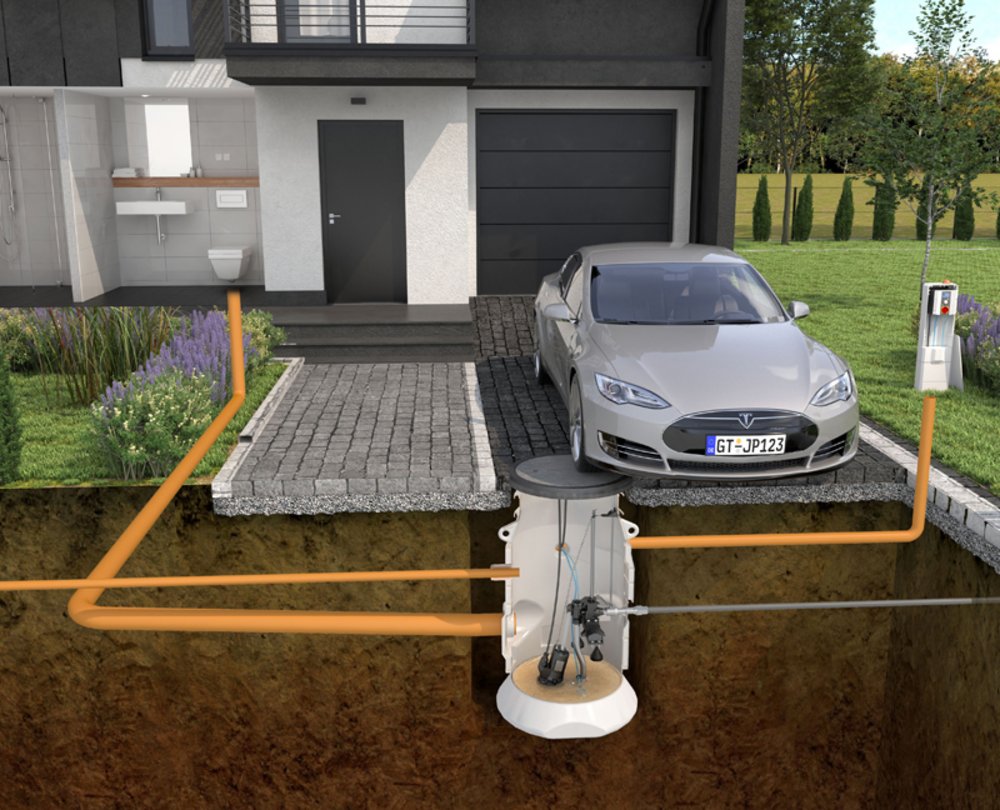

With pressure sewer systems, small domestic pumping stations carry waste water from individual houses or groups of houses to a pressure pipe network which conducts the sewage away for treatment.

Small pipe diameters save money

In addition, the flow processes in the pipe network are regulated and assisted by compressed air irrigation stations.

With pressure drainage, only the wastewater is discharged, so the pipe dimensioning can already be much smaller than pipe or sewer systems in the combined system. In rural areas, rainwater can usually be infiltrated directly on site.

Components of the pressure sewerage system

Pump shaft

The collecting space (pump shaft) doubles as an emergency overflow space. One or more buildings can be connected to a chamber and pumping station.

- Ventilation

- Sufficient power supply

- Control and alarm equipment

- Level indicator in collecting chamber for automatic control of the pumps

- Stop valve with backflow preventer (ball valve) and irrigation connection option

- The emergency overflow volume must be 25% of the daily inflow.

Pump technology

Submersible pumps with MultiCut cutting mechanisms are used in the domestic pumping station. The cutting system ensures that wrongly directed sewage, such as cloths or sanitary products, are safely reduced and removed. Cutting-wheel pumps enable the use of small pressure lines from DN 32. The power necessary should not exceed a connected load of 16 amperes. The power supply must already have been coordinated with the energy provider in the planning phase.

Compressor stations

Pressure pipe irrigation stations automatically introduce compressed air into the system to support the flow processes in the pressure lines. This results in the following:

- The waste water spends less time in the pipes

- Deposits are broken down by high irrigation speeds

- Oxygen is introduced into the waste water

- The build-up of hydrogen sulphide is prevented.

Pressure pipe irrigation stations must be arranged such that, if possible, they feed into all critical pipe areas.

Pump shaft

The collecting space (pump shaft) doubles as an emergency overflow space. One or more buildings can be connected to a chamber and pumping station.

- Ventilation

- Sufficient power supply

- Control and alarm equipment

- Level indicator in collecting chamber for automatic control of the pumps

- Stop valve with backflow preventer (ball valve) and irrigation connection option

- The emergency overflow volume must be 25% of the daily inflow.

Pump technology

Submersible pumps with MultiCut cutting mechanisms are used in the domestic pumping station. The cutting system ensures that wrongly directed sewage, such as cloths or sanitary products, are safely reduced and removed. Cutting-wheel pumps enable the use of small pressure lines from DN 32. The power necessary should not exceed a connected load of 16 amperes. The power supply must already have been coordinated with the energy provider in the planning phase.

Compressor stations

Pressure pipe irrigation stations automatically introduce compressed air into the system to support the flow processes in the pressure lines. This results in the following:

- The waste water spends less time in the pipes

- Deposits are broken down by high irrigation speeds

- Oxygen is introduced into the waste water

- The build-up of hydrogen sulphide is prevented.

Pressure pipe irrigation stations must be arranged such that, if possible, they feed into all critical pipe areas.

Illustrative videos and brochures

Pressure drainage videos and animations

Brochures

Gravity pipe versus pressure pipe

| Pressure drainage | Gravity sewer system |

|---|---|

| Small pipes from DN 32 | Large dimensioned pipes |

| High installation rates per day | Earthworks for months |

| Parallel laying of drinking water, electricity, telephone, wastewater e.g. with cable plow possible | No parallel laying of different pipes possible |

| Installation independent of the condition of the soil | Soil layers like e.g. sand and groundwater level have to be respected |

| Laying independent of the terrain | Gradient should be noted, eventually intermediate pumping stations have to be installed |

| Less field damages | High field damages due to earthworks |

| Less disruptions to residents due to fast laying | Higher disruptions to residents |

| Traffic flow is not disturbed | Road closures neccessary |

| Long-lasting flexible PE-HD-pipes | Risk of breaking of concrete pipe |