MultiCut 08/2 MS

JP50345| Mechanikai adatok | |

|---|---|

| Szivattyú | függőlegesen egyfokozatú |

| Csapágy | Zsírkenésű golyóscsapágyak |

| Motoroldali tömítés | 2-szeres tengelytömítés |

| Olajkamra | igen |

| Közegoldali tömítés | SiC csúszógyűrűs tömítés |

| Szárazmenetbiztos | igen |

| Járókerék | Vortex-járókerék, GFK |

| Motorház | Nemesacél |

| Szivattyúház | szürkeöntvény |

| Elárasztható | igen |

| Nyomócsonk | DN 32 |

| Súly | 17,2 kg |

| Villamos adatok | |

|---|---|

| Kapcsolás | kapcsolóautomatikával |

| Feszültség | 3/PE~400 V |

| Motorteljesítmény P1 | 1,65 kW |

| Motorteljesítmény P2 | 1,24 kW |

| Áram | 2,8 A |

| Hálózati vezeték | 10m H07RN-F |

| Kábelerek | 4G1,0 |

| Védettség | IP 68 |

| Tekercstermosztát | igen |

| Motorvédelem | a motorban |

| Csatlakozó | CEE-16A |

| S3 | 10 % |

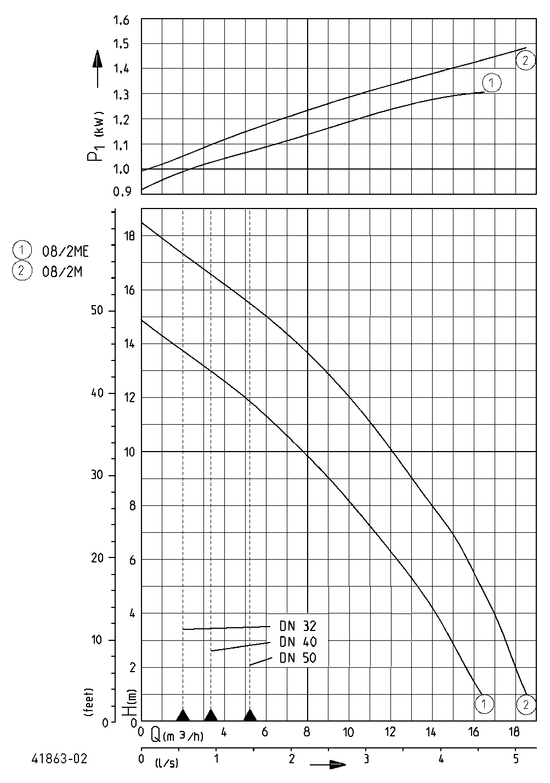

| Teljesítmény | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Szállítási magasság H [m] | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Szállítási mennyiség Q [m³/h] | 18,5 | 18 | 17,5 | 17 | 16,5 | 15,5 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 7,5 | 6 | 4,5 |

Konstrukciós változtatások joga fenntartva – Teljesítménytolerancia ISO 9906 szerint

Az EN12056 szabvány szerint a nyomócsőben a minimális áramlási sebességnek 0,7 m/s-nak kell lennie. A Q-H diagramon az alkalmazási határértékként (szaggatott vonal) látható.

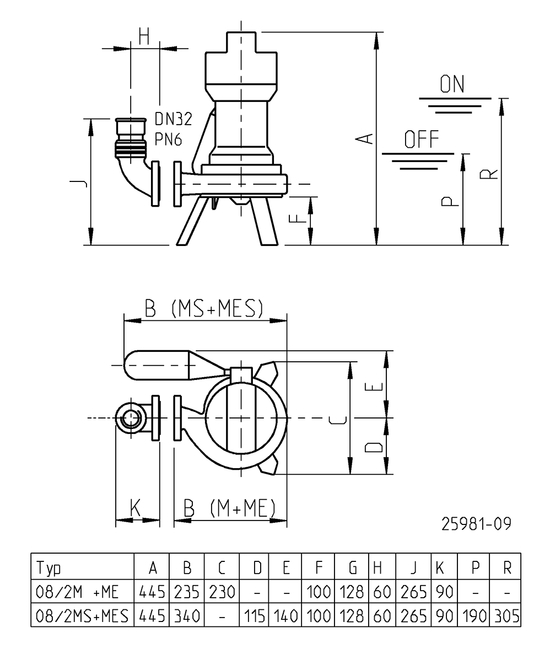

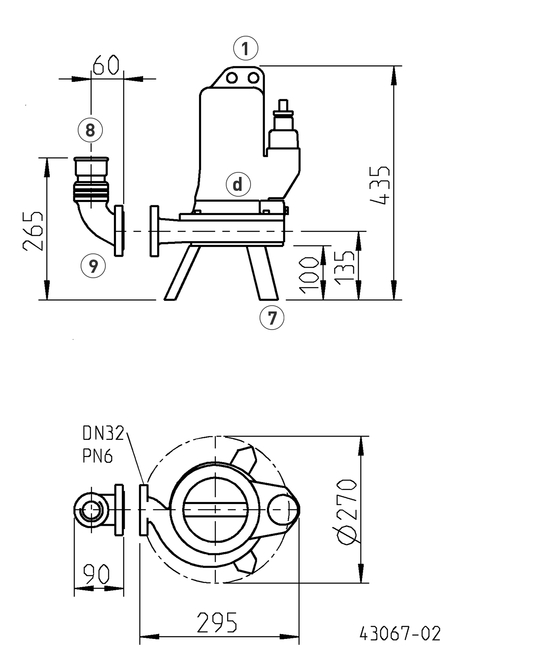

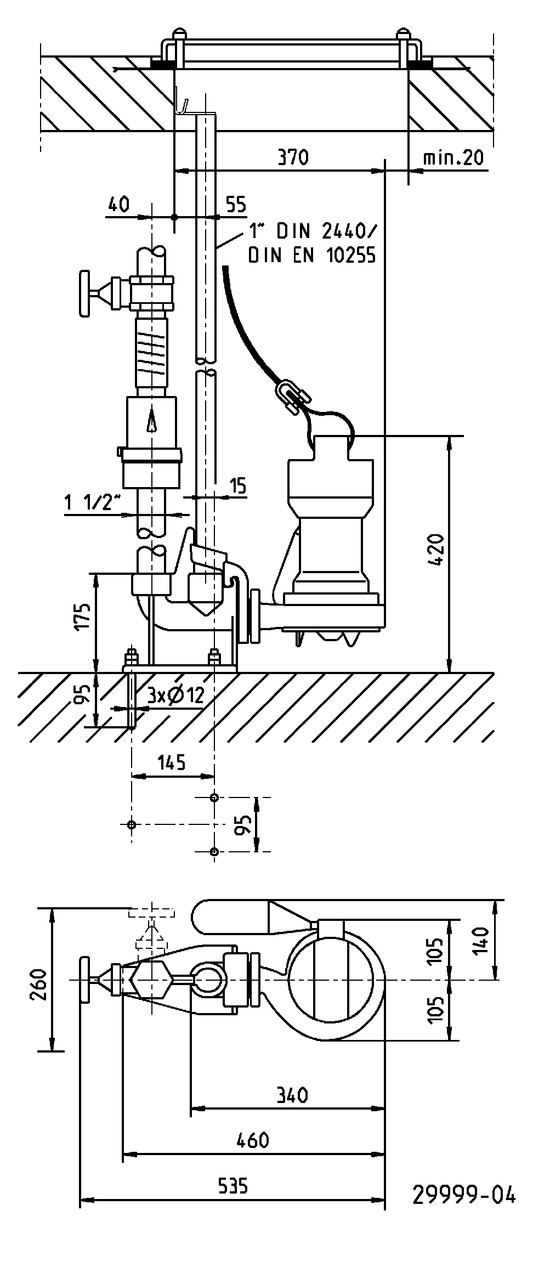

Fő méretek 08/2 M (mm)

Fő méretek 08/2 M, EX (mm)

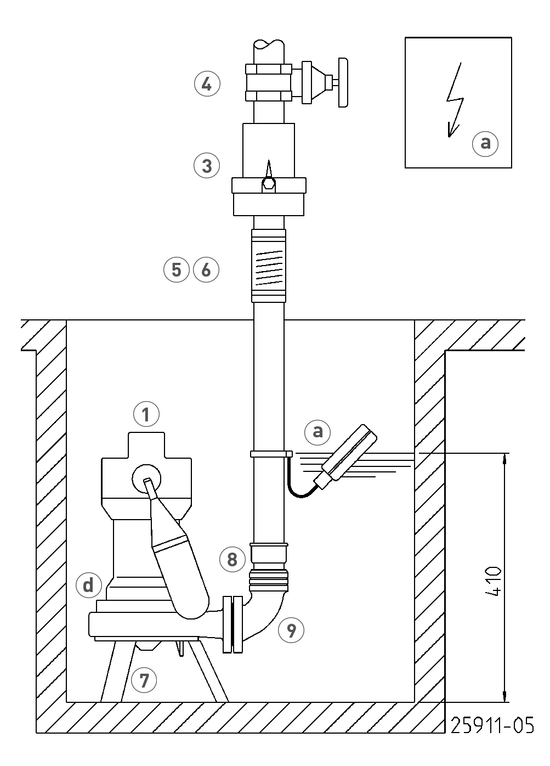

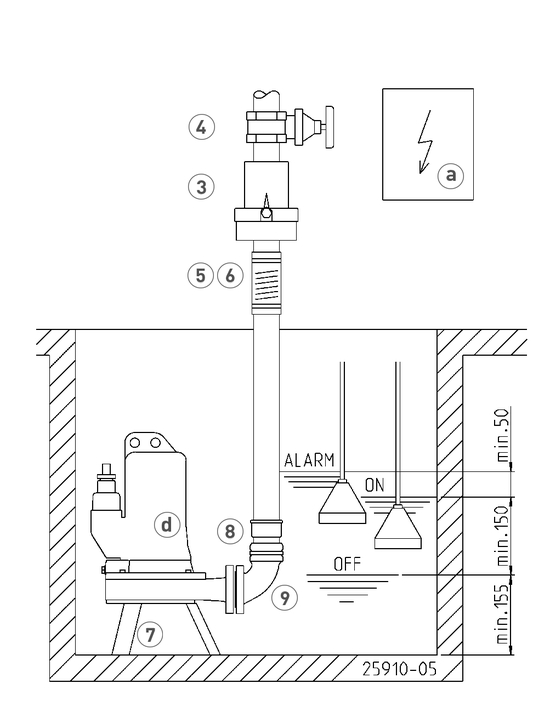

Beépítési példa támaszlábakkal

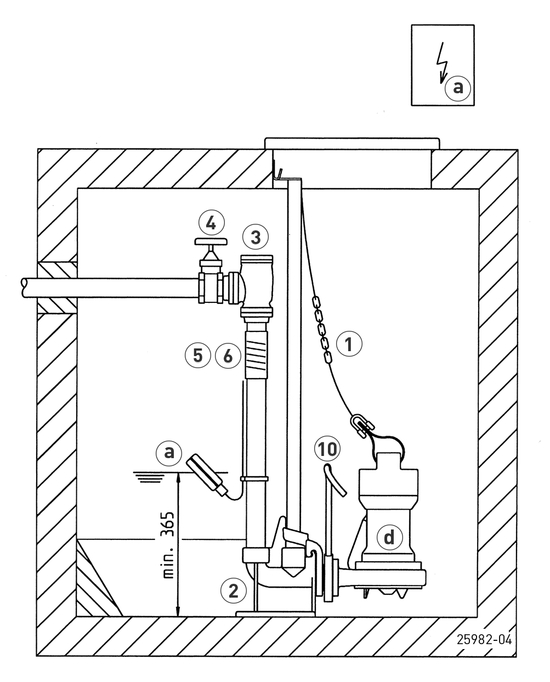

EX támaszláb beépítési példa

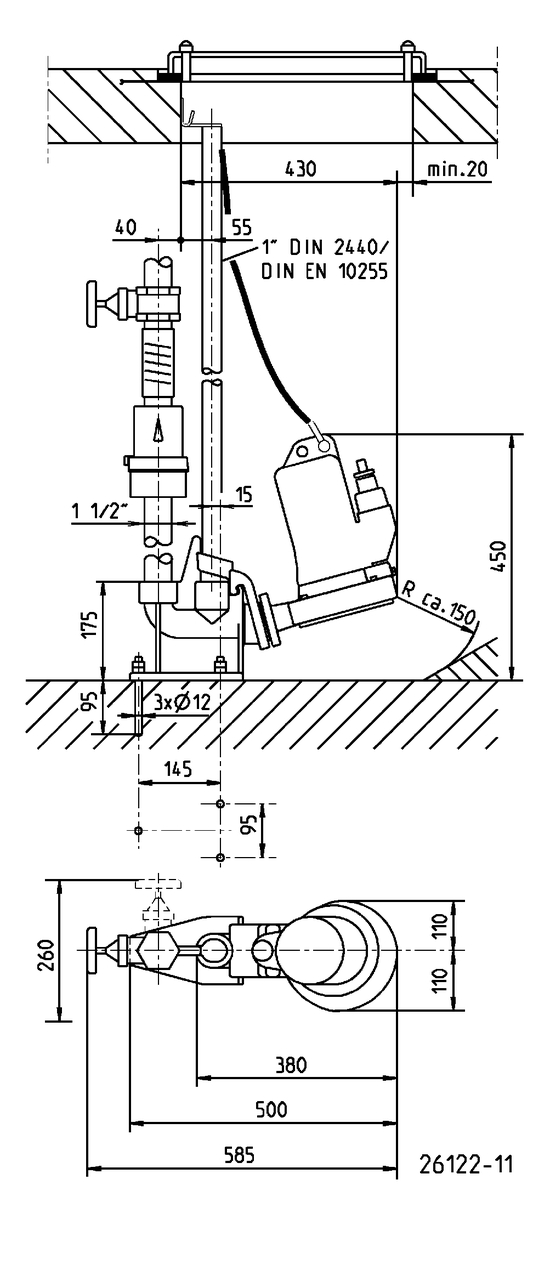

Beépítési példa csúszócsöves rendszerre

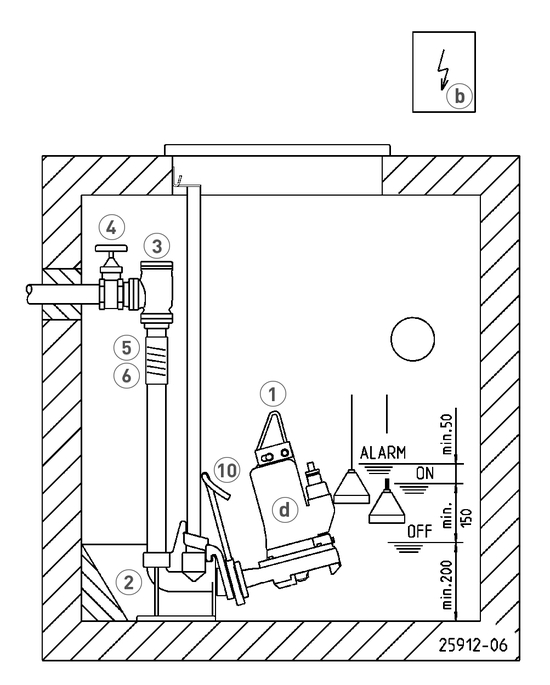

Beépítési példa EX vezetőcsőrendszerre

Beépítési példa csúszócsöves rendszerre

Beépítési példa EX vezetőcsőrendszerre

Mono elrendezés – minimális aknaméret (cm)

GR nélkül: 40x40

GR-rel és visszacsapószeleppel: 40x65

GR-rel és golyós szeleppel: 40x65

Duo elrendezés - minimális tengelyméret (cm)

GR és visszacsapószelep nélkül, visszacsapószelep: 60x60

GR és kúpos sarokszelep nélkül: 60x80

GR-rel és kettős visszacsapószeleppel: 60x60

GR-rel és visszacsapószeleppel vagy csappantyúval: 65x85

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Lánc | ||||||

| tesztelt, 2,5 m, 320 kg, 5 függesztőkar (EN 818 mod.) | JP45901 | |||||

| tesztelt, 5,0 m, 320 kg, 8 függesztőkar (EN 818 mod.) | JP45902 | |||||

| tesztelt, 7,5 m, 320 kg, 11 függesztőkar (EN 818 mod.) | JP47365 | |||||

| Bilincs, tesztelt, 630 kg, rozsdamentes acél | JP45904 | |||||

| Hordszíj | ||||||

| bilinccsel | JP45168 | |||||

| Vezetőcső rendszer | ||||||

| GR 35 | 1½” belső menet a Multicut 08-hoz robbanásvédelem nélkül | JP29953 | ||||

| Visszacsapószelep | ||||||

| R40 EN 12050-4 | 1½“ (DN 40), PN 4 | 150x120 (ma x szé) | JP00317 | |||

| R50 EN 12050-4 | 2“ (DN 50), PN 4 | 150x120 (ma x szé) | JP00326 | |||

| Golyós visszacsapószelep | ||||||

| KE40 EN 12050-4 | 1½“ (DN 40), PN 6 | 170x125 (ma x szé) | JP47974 | |||

| K50 EN 12050-4 | 2“ (DN 50), PN 6 | 185x155 (ma x szé) | JP44782 | |||

| Tolózár | ||||||

| Réz, 1½“ (DN 40), PN 16 | 125x60 (ma x szé) | JP44786 | ||||

| Nemesacél, 1½“ (DN 40), PN 16 | 125x80 (ma x szé) | JP48403 | ||||

| Réz, 2“ (DN 50), PN 16 | 140x70 (ma x szé) | JP44787 | ||||

| Elasztikus kötés | ||||||

| + Bilincs, 1½“ (DN 40), PN 4 | 120x50 (ma x mé) | JP50902 | ||||

| + Bilincs, 2“ (DN 50), PN 4 | 150x63 (ma x mé) | JP50903 | ||||

| Tartólemez | ||||||

| légharangokhoz (a helyszíni aknákban) | JP50213 | |||||

| Csőcsatlakoztatás | ||||||

| 1¼“ (belső menet) | JP16870 | |||||

| Öblítőcső | ||||||

| I-M típusú rozsdamentes acél csatlakozó karimával (a PKS-B 800 nem tartalmazza) | JP40333 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Cikkszám | ||||||

| Riasztó jeladó | ||||||

| AG3 | Úszókapcsoló, hálózatfüggő, potenciálmentes érintkező, 3 m kábel | JP44891 | ||||

| AG10 | Úszókapcsoló, hálózatfüggő, potenciálmentes érintkező, 9,5 m kábel | JP44892 | ||||

| Akkumulátor | ||||||

| 9 V, hálózatfüggetlen riasztáshoz | JP44850 | |||||

| Tömítettségellenőrzés | ||||||

| DKG szonda olajkamra ellenőrzéshez | JP44900 | |||||