Sewage lifting stations

COMPLI 500

The sewage lifting station with larger storage volume of 117 litres

Areas of application: Single- and two-family houses

5-year warranty for specialist tradesmen when registered

at www.hauptsachejung.de/en

Made in Germany

- Ready to connect

- Submersible

- Clamp-type inlet flange

- Versatile connection facilities

- PE-tank 117 l

- Vortex impeller

- With mounted swing-type check valve

With its performance graduations, the Compli 500 lifting station has been designed for use in detached houses with increased domestic waste-water inlet and for a larger storage capacity. During the design work, special attention was given to easy handling (weight !), space-saving and uncomplicated installation.

The submersible unit is permitted for general use in areas subject to flooding. The control unit has to be fitted in a well ventilated flood-proof room. The PE tanks has freely accessible drains, a cleaning opening at the top and a clamp-type inlet flange for an easy installation.

The inlet height can be variegated according to the feeding pipe:

DN100: 180-205 mm (left), 250-300 mm (center) and 290-340 mm (right), each continuously adjustable; DN150/DN 50: 180 mm (left), 275 mm (center) and 315 mm (right)

For the connection of a DN 100 feeding pipe a reducer DN 150/100 is enclosed. The tank has vertical inlet in DN 150 or DN 100. If not in use, the rear inlet must be closed with the plug set DN 150 (accessory).

The vortex impeller of the pump with 70 mm free passage offers the safety you can rely on.

The Compli sewage lifting station can be integrated into a smart infrastructure. The FTJP radio transmitter is connected to the potential-free contact of the lifting station. It is now possible to transmit the switching status (e.g. an alarm message) to an EnOcean-capable smart home gateway (Wibutler, Afriso, Homee).

Ready for plug in sewage lifting unit according to EN 12050-1 with clamp flange DN 150, reducer DN 150/100, built-on subm. sewage pump and connection flange DN 80 PN 10 with pipe socket Ø 110 mm, reducer ring Ø 110 up to Ø 90, with mounted swing-type check valve, elastic connection c/w hose clamps, PVC collar DN 70 for ventilation connection, autom. level controller, control unit (IP 44) c/w motor protection, motor contactor, transformer, mains-dependent optional confirmable alarm unit and potential noc-contact for collective failure messages, with optical display of sense of rotation, alarm and operation, and manual-0-automatic switch as well as an adjustable maintenance interval display.

Cable between tank and control 4 m, cable between control and plug 1.5 m.

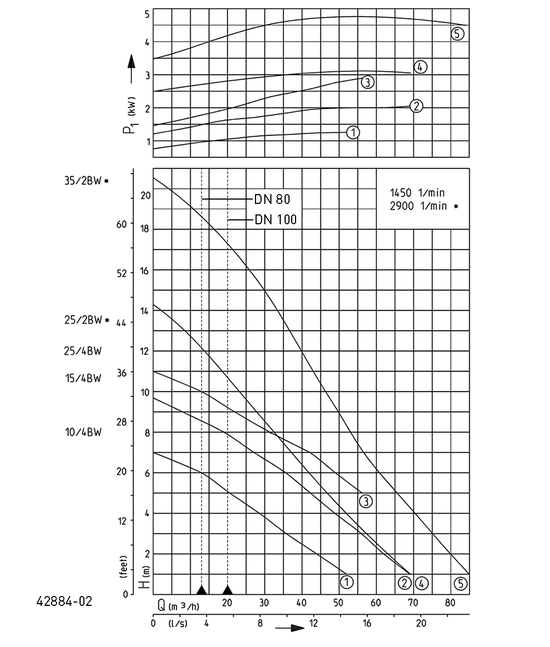

| Delivery head Hmax | 20 m |

| Flow rate Qmax | 85 m³/h |

| Free passage | 70 mm |

| Pressure outlet | DN 80 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

5 results

| Type | Code No. | Motor rating P1 | Motor rating P2 | Current | Oil chamber | Impeller |

|---|---|---|---|---|---|---|

JP50091 | 1.25 kW | 0.87 kW | 2.2 A | No | Vortex impeller, GFK | |

JP50092 | 2.2 kW | 1.7 kW | 3.9 A | No | Vortex impeller, GFK | |

JP50093 | 3 kW | 2.2 kW | 5.1 A | No | Vortex impeller, GFK | |

JP50094 | 3.3 kW | 2.6 kW | 5.4 A | Yes | Vortex impeller, grey cast iron | |

JP50095 | 4.8 kW | 4 kW | 8.2 A | Yes | Vortex impeller, grey cast iron |