K2 Plus

JP46589| Mechanical data | |

|---|---|

| Shaft | Stainless steel |

| Impeller | Vortex impeller, plastic |

| Usable capacity | 0.9 l |

| Weight | 3.1 kg |

| Electrical data | |

|---|---|

| Voltage | 1/N/PE~230 V |

| Motor rating P1 | 65 W |

| Current | 0.58 A |

| Power line | 2m H05VV-F |

| Wires | 3G0,75 |

| Type of enclosure | IP 24 |

| Motor protection | Thermostat |

| Plug | Safety |

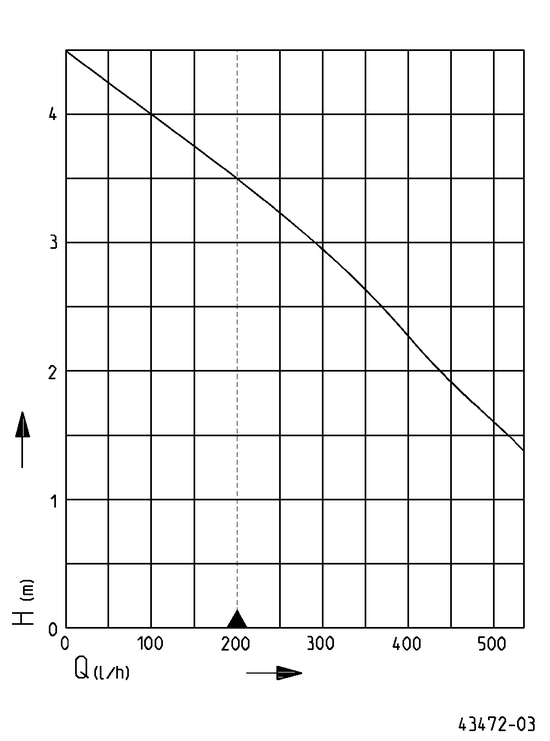

| Performance | |||||

|---|---|---|---|---|---|

| Delivery head H [m] | 1.5 | 2 | 2.5 | 3 | 3.5 |

| Flow rate Q [l/h] | 520 | 440 | 365 | 290 | 200 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

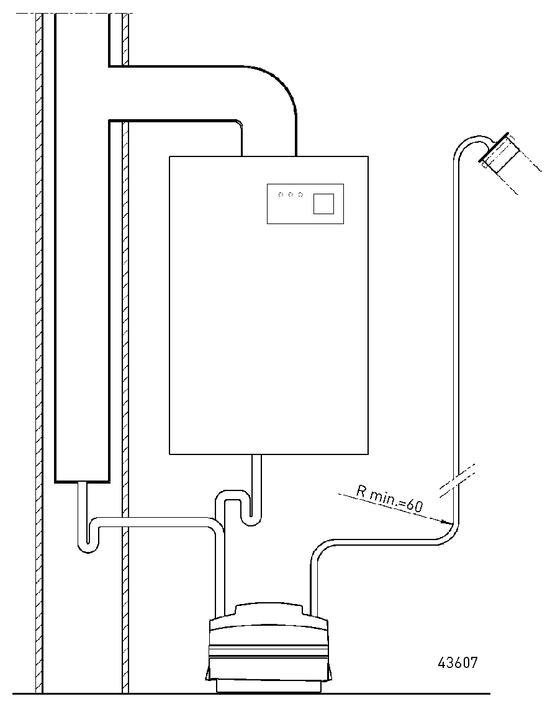

Condensates taken from condensing boiler technology are very aggressive. You will find corresponding information in the ATV working paper „Condensates from condensing boilers“, ATV-DVWL-A 251 (2011). The K2 plus is designed for use at room temperatures, a pH value of ≥ 2.7 and a maximum inlet temperature of 104 °F (40 °C). Should the condensate values fall below the above-mentioned pH value even for a short time, a neutralisation has to be installed between therm and pump. The local requirements (local discharge regulation) as well as the neutralisation obligations of the ATV working paper are to be considered as well. Guiding values for untreated condensate can be found in the mentioned ATV working paper, table B.1. For condensate lines only approved materials in accordance with ATV working paper table 4 are to be used. If not already integrated in the unit all inlets must be provided with a siphon trap (emission trap). It is generally not permitted to install the unit outdoors.

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Hose extension | ||||||

| 6 m, with hose connector | JP27993 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Smart Home | ||||||

| FTJP radio transmitter | JP47209 | |||||