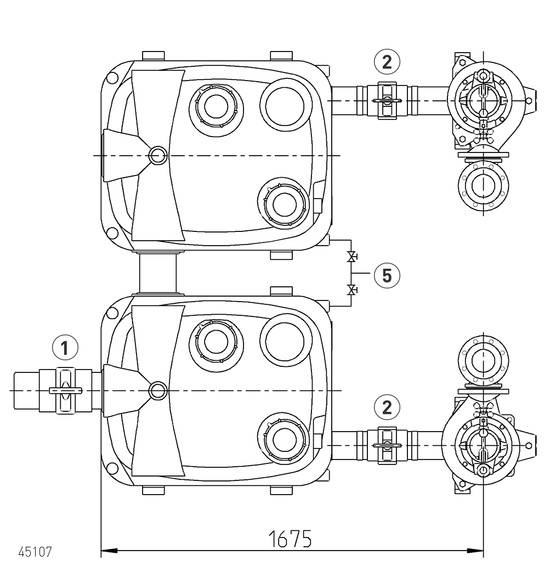

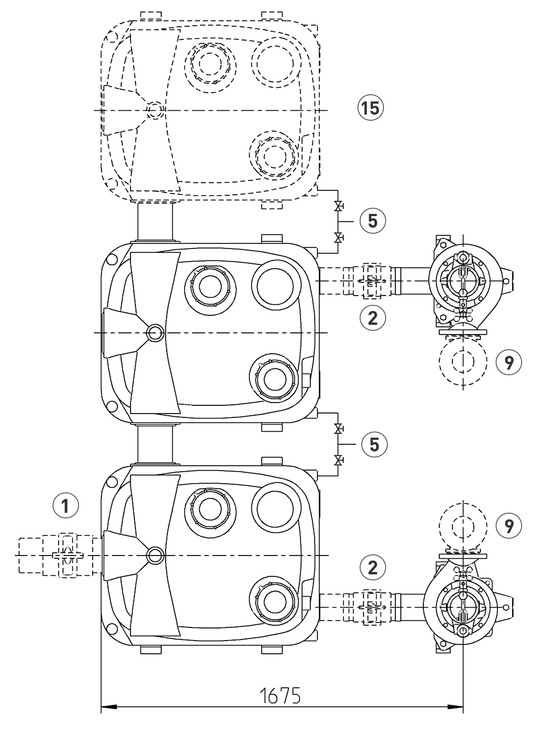

compli 2575/4 B6 HL

JP50137| Mechanical data | |

|---|---|

| Pump | Vertical single-stage |

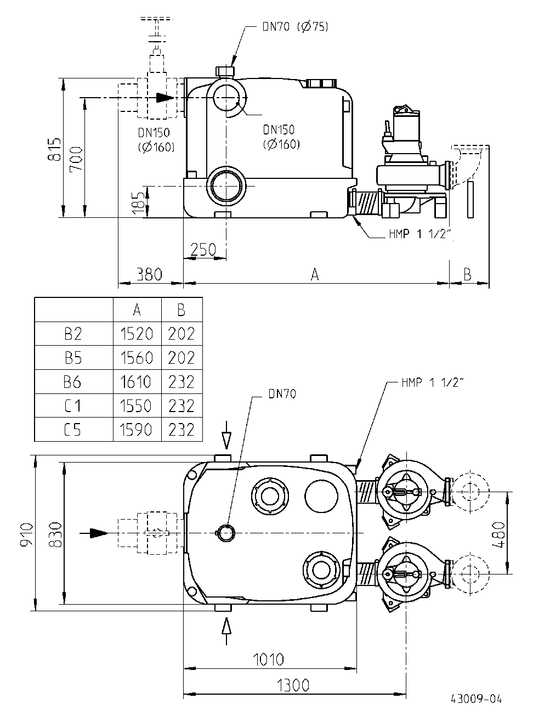

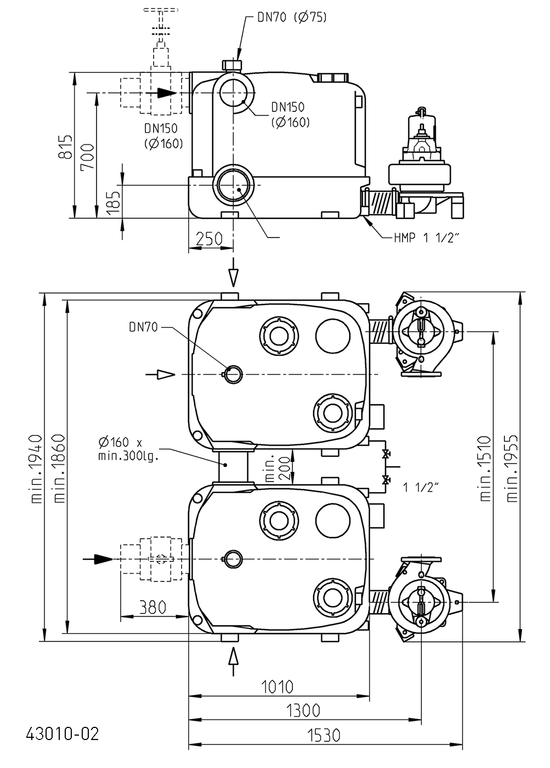

| Free passage | 70 mm |

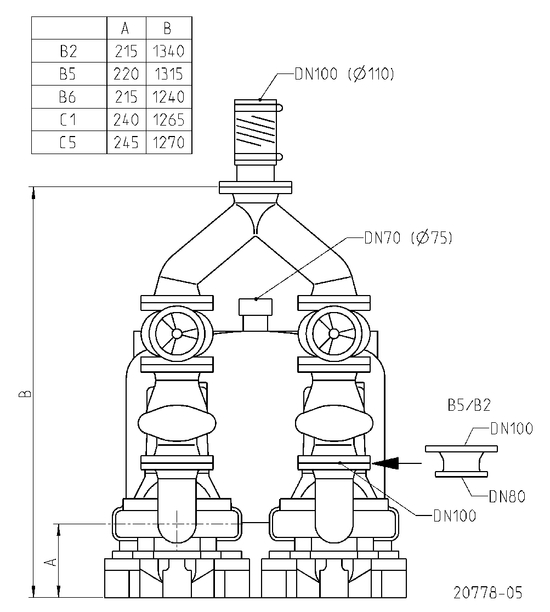

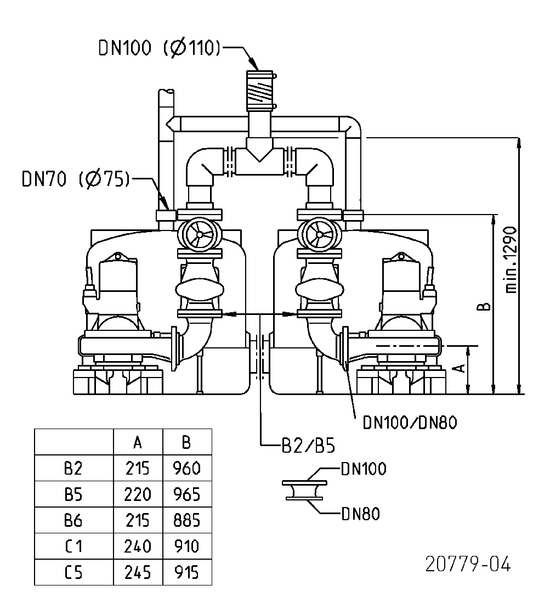

| Pressure pipe | DN 100 |

| Bearing | Ball bearings, grease-lubricated |

| Oil chamber | Yes |

| Run dry protection | Yes |

| Impeller | Cannel impeller, grey cast iron |

| Motor housing | Grey cast iron |

| Pump housing | Grey cast iron |

| Submersible | Yes |

| Pressure outlet | DN 100 |

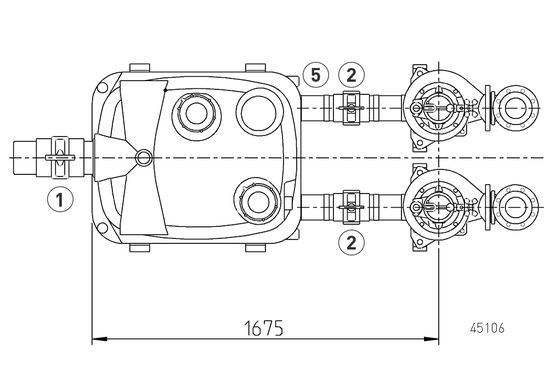

| Tank capacity | 500/1000 l |

| Weight | 405 kg |

| Electrical data | |

|---|---|

| Voltage | 3/N/PE~400 V |

| Motor rating P1 | 7.2 kW |

| Motor rating P2 | 5.9 kW |

| Current | 12.8 A 7.4 A |

| Power line | 10m H07RN-F |

| Wires | 10G2,5 |

| Type of enclosure | IP 68 |

| Insulation class | F |

| Winding thermostat | Yes |

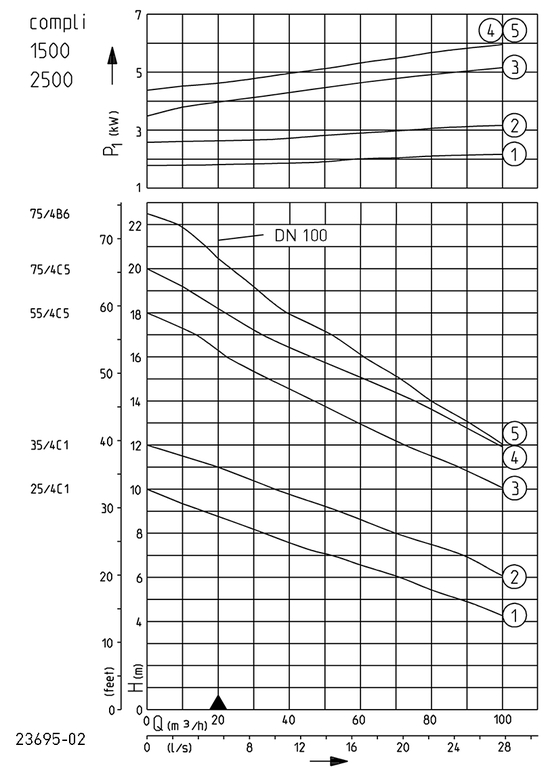

| Performance | |||||

|---|---|---|---|---|---|

| Delivery head H [m] | 13 | 14 | 16 | 18 | 20 |

| Flow rate Q [m³/h] | 91 | 82 | 62 | 41 | 24 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

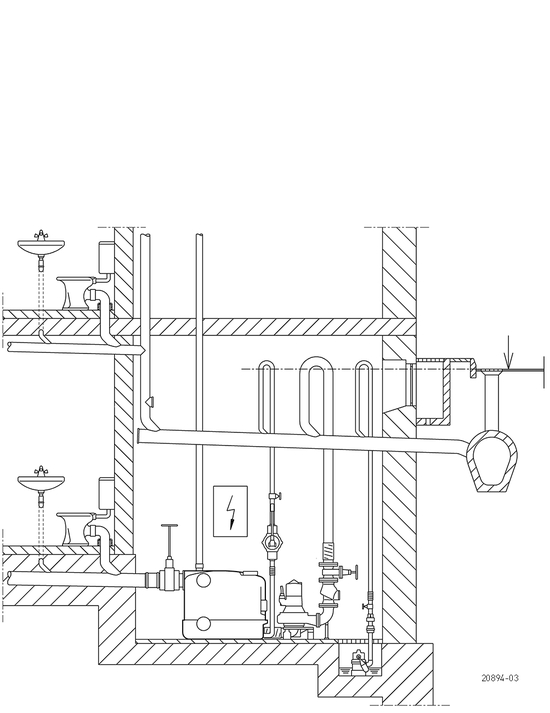

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

Sewage lifting units are to be used in building drainage systems in accordance with the construction and testing principles of EN 12050 for the transport of faeces and domestic wastewater (EN 12056, DIN 1986-3). They are to be installed in accordance with the regulations of EN 12056-4 with collection tanks inside buildings, 60 cm free-standing for operation and maintenance. The pressure pipe has to be passed above the locally defined backflow level and a non-return valve tested according to EN 12050-4 must be installed. The ventilation pipe must be passed above the roof.

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Inlet gate valve PVC | ||||||

| with two pipe sockets, DN 150, PN2.5 | 660x450 (HxW) | JP28591 | ||||

| Stop valve | ||||||

| with two pipe sockets, DN 100, PN1, 300x295 (HxW) | JP45173 | |||||

| Sluice valve | ||||||

| DN 100, PN 10, EN 1171 | 345x190 (HxB) | JP00329 | ||||

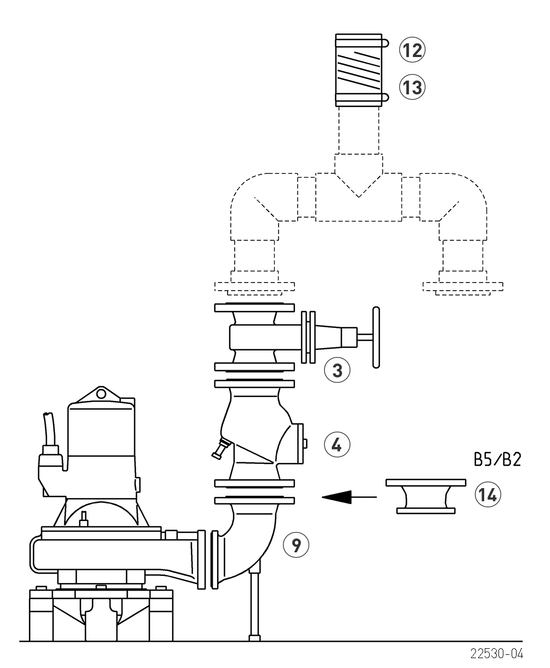

| Swing-type check valve | ||||||

| R 101 EN 12050-4 | DN 100, PN 4, flange PN 10, EN 558, 300 (H) | JP00325 | ||||

| R 100 G EN 12050-4 | DN 100, PN 4, flange PN 10, EN 558, with counter weight, 300(H) | JP00324 | ||||

| Hand diaphragm pump | ||||||

| for emergency purposes (up to Hgeo 15 m) | 640x1½” (HxD) | JP00255 | ||||

| Stop valve | ||||||

| brass, 1½“ (DN 40), PN 16 | 125x60 (HxB) | JP44786 | ||||

| Elastic connection | ||||||

| + Hose band clamps, 1½“ (DN 40), PN 4 | 120x50 (HxD) | JP50902 | ||||

| Flanged connection | ||||||

| B 80 (similar Q-piece 90°), DN 80 PN10/PN6 | 150x100 (HxB) | JP00578 | ||||

| C 100 (similar Q-piece 90°), DN 100 PN10/PN6 | 175x120 (HxB) | JP00579 | ||||

| Flanged Y-pipe | ||||||

| DN 100/100/100 | 355x480(HxB), PN 10 | JP00203 | ||||

| Flanged spigot | ||||||

| DN 100 PN 10, F-KS | 153x110 (HxD) | JP08673 | ||||

| DN 100 PN 10, F-piece | 100x114 (HxD) | JP00688 | ||||

| Elastic connection | ||||||

| + Clamps, 2“ DN 100, PN 4 | 200x110 (HxD) | JP50905 | ||||

| + Clamps ,2“ DN 100, PN 4 | 200x114 (HxD) | JP50906 | ||||

| Tank | ||||||

| 500 l | JP45945 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Rechargeable battery | ||||||

| 9 V, for mains independent alarm | JP44850 | |||||

| Seal leak detector | ||||||

| DKG (für die Ölkammer) | JP44900 | |||||

| Smart Home | ||||||

| FTJP radio transmitter | JP47209 | |||||