MultiCut 08/2 MES

JP50343| Mechanical data | |

|---|---|

| Pump | Vertical single-stage |

| Bearing | Ball bearings, grease-lubricated |

| Seal on motor side | Duplex rotary shaft seals |

| Oil chamber | Yes |

| Seal on medium side | SiC mechanical seal |

| Run dry protection | Yes |

| Impeller | Vortex impeller, GFK |

| Motor housing | Stainless steel |

| Pump housing | Grey cast iron |

| Submersible | Yes |

| Pressure outlet | DN 32 |

| Weight | 16.6 kg |

| Electrical data | |

|---|---|

| Ciruit | With built-in level control |

| Voltage | 1/N/PE~230 V |

| Motor rating P1 | 1.37 kW |

| Motor rating P2 | 0.98 kW |

| Current | 6 A |

| Power line | 10m H07RN-F |

| Wires | 3G1,0 |

| Type of enclosure | IP 68 |

| Winding thermostat | Yes |

| Motor protection | In motor |

| Plug | Safety |

| S3 | 10 % |

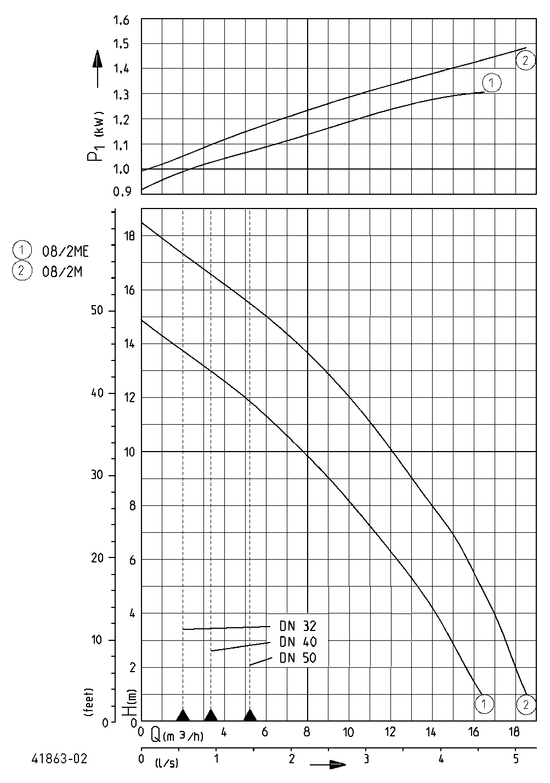

| Performance | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Delivery head H [m] | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Flow rate Q [m³/h] | 16.5 | 15.5 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 7.5 | 6.5 | 5 | 3.5 | 1.5 |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

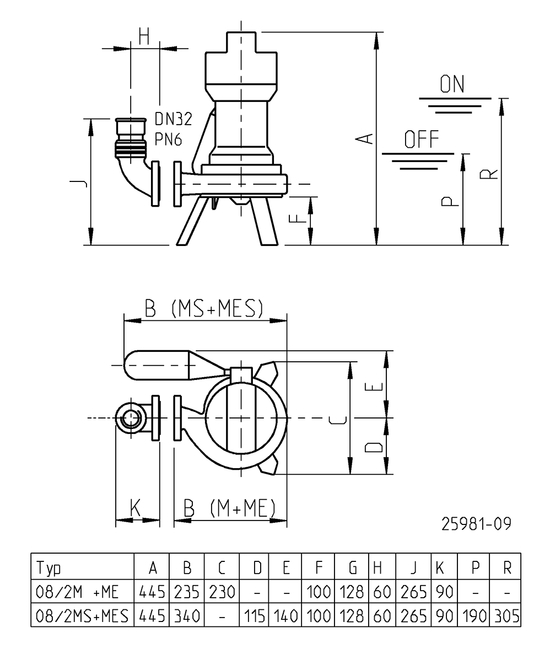

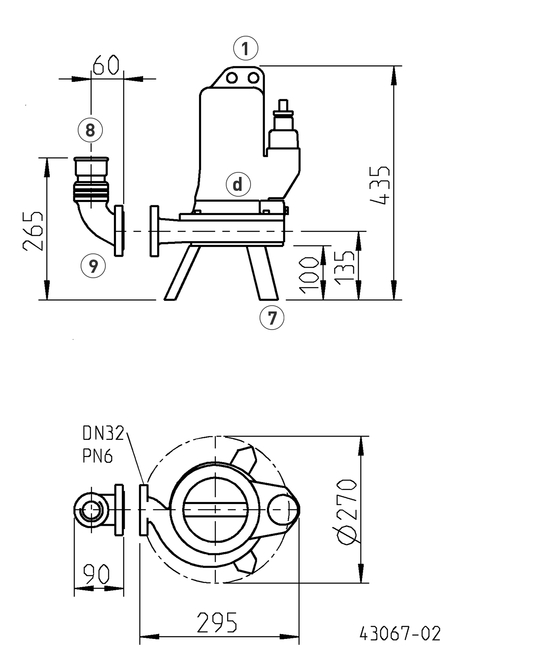

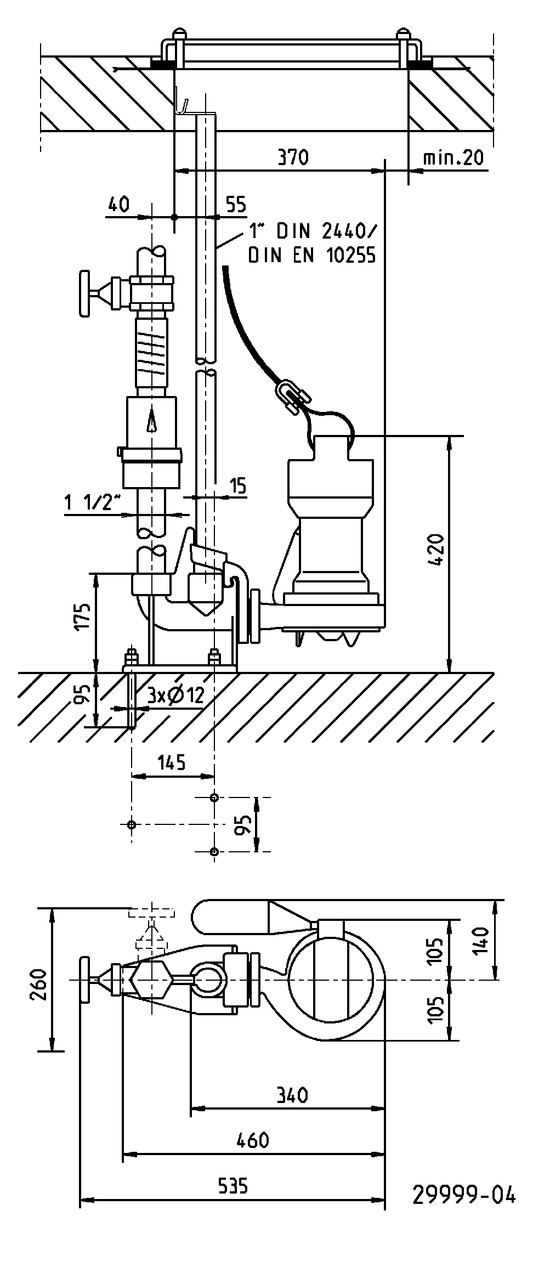

Dimensions 08/2 M (mm)

Dimensions 08/2 M, EX (mm)

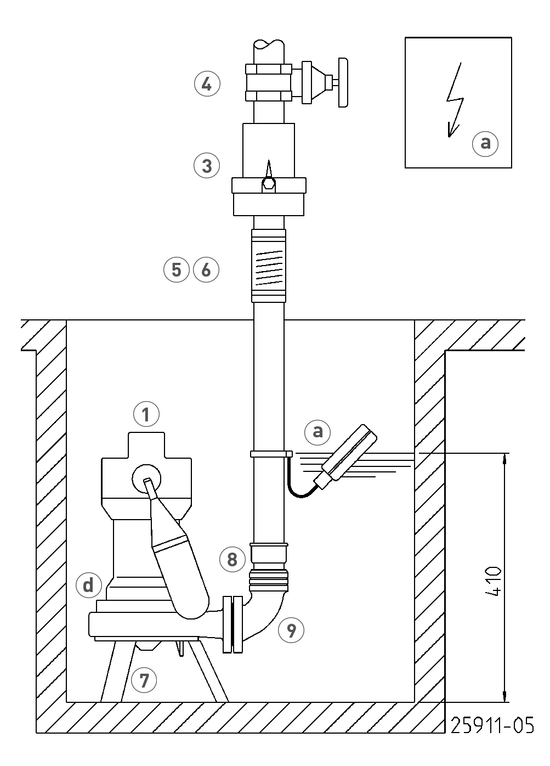

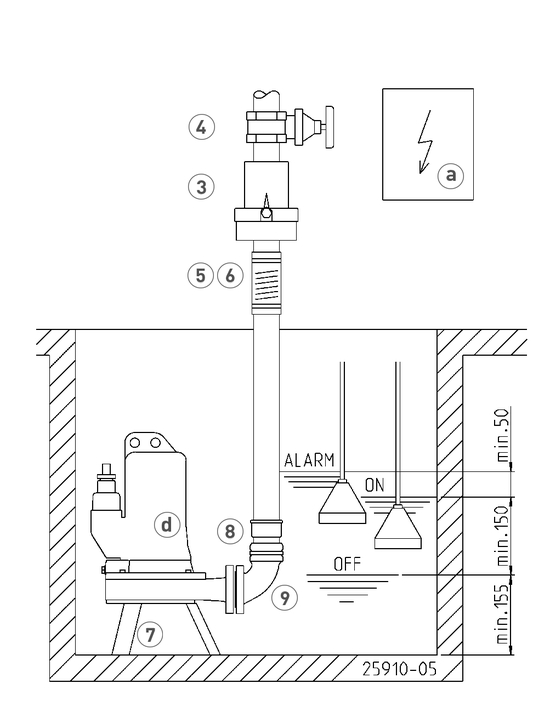

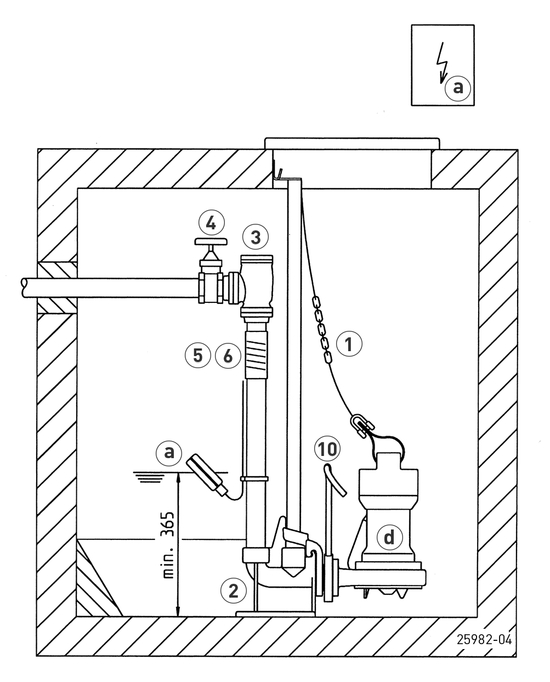

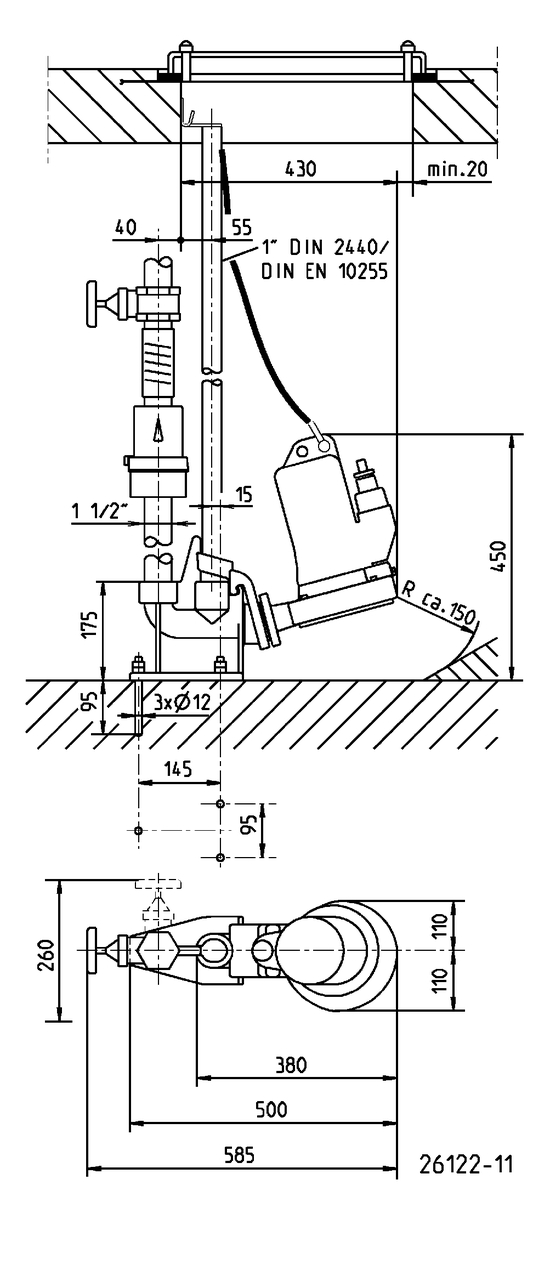

Example of pump base installation

Example of pump base installation with ex-proof

Example of guide rail installation

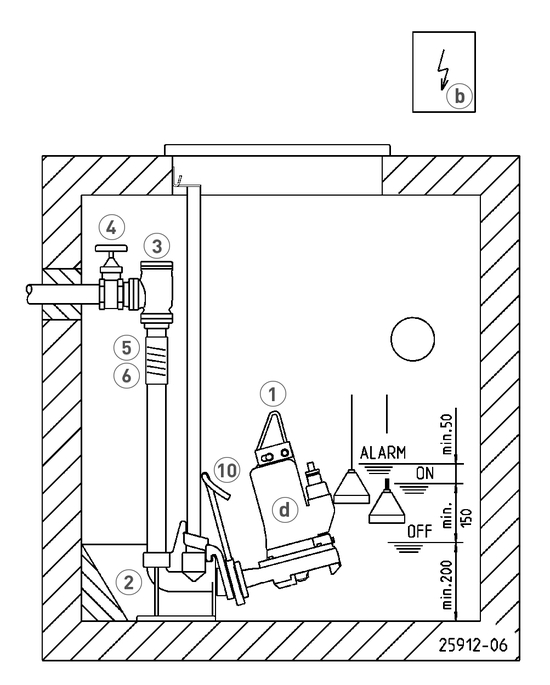

Example of guide rail installation with ex-proof

Example of guide rail installation

Example of guide rail installation with ex-proof

Single unit - min. sump (cm)

without GR: 40x40

with GR and swing-type check valve: 40x65

with GR and ball-type check valve: 40x65

Duplex unit - min. sump (cm)

without GR and swing-type check valve, check valve: 60x60

without GR and elbow-ball check valve: 60x80

with GR and duplex swing-type check valve: 60x60

with GR and duplex swing-type check valve or -valve: 65x85

| Mechanical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Chain | ||||||

| certified, 2.5 m, 320 kg, 5 rings (EN 818 mod.) | JP45901 | |||||

| certified, 5.0 m, 320 kg, 8 rings (EN 818 mod.) | JP45902 | |||||

| certified, 7.5 m, 320 kg, 11 rings (EN 818 mod.) | JP47365 | |||||

| Shackle, certified, 630 kg, stainless steel | JP45904 | |||||

| Webbing | ||||||

| with shackle | JP45168 | |||||

| Guide rail system | ||||||

| GR 35 | 1 1/2" female thread for MultiCut 08 without Ex-proof | JP29953 | ||||

| Swing-type check valve | ||||||

| R40 EN 12050-4 | 1½“ (DN 40), PN 4 | 150x120 (HxB) | JP00317 | |||

| R50 EN 12050-4 | 2“ (DN 50), PN 4 | 150x120 (HxB) | JP00326 | |||

| Ball-type check valve | ||||||

| KE40 EN 12050-4 | 1½“ (DN 40), PN 6 | 170x125 (HxB) | JP47974 | |||

| K50 EN 12050-4 | 2“ (DN 50), PN 6 | 185x155 (HxB) | JP44782 | |||

| Stop valve | ||||||

| brass, 1½“ (DN 40), PN 16 | 125x60 (HxB) | JP44786 | ||||

| stainless steel, 1½“ (DN 40), PN 16 | 125x80 (HxB) | JP48403 | ||||

| brass, 2“ (DN 50), PN 16 | 140x70 (HxB) | JP44787 | ||||

| Elastic connection | ||||||

| + Hose band clamps, 1½“ (DN 40), PN 4 | 120x50 (HxD) | JP50902 | ||||

| + Hose band clamps, 2“ (DN 50), PN 4 | 150x63 (HxD) | JP50903 | ||||

| Retaining plate | ||||||

| for air bells (in concrete sumps from Ø 1 m) | JP50213 | |||||

| Pipe connection | ||||||

| 1 1/4" (female thread) | JP16870 | |||||

| Flushing tube | ||||||

| Type I-M stainless steel with connection flange (not PKS-B 800) | JP40333 | |||||

| Electrical accessory | ||||||

|---|---|---|---|---|---|---|

| Code No. | ||||||

| Alarm unit | ||||||

| AG3 | subm. ball contact switch, mains dependent, potential-free contact,3 m cable | JP44891 | ||||

| AG10 | subm. ball contact switch, mains dependent, potential-free contact, 9.5 m cable | JP44892 | ||||

| Rechargeable battery | ||||||

| 9 V, for mains independent alarm | JP44850 | |||||

| Seal leak detector | ||||||

| DKG (für die Ölkammer) | JP44900 | |||||