Sewage pumps

MultiCut 08

- Reliable solids transport due to improved cutting technology

- External adjustable cutting mechanism

- Controllable oil chamber

- Installed motor protection

- SiC mechanical seal independent of sense of rotation

- Moisture-sealed cable inlet with plug-in cable connection

- Ex-version: Impeller and replaceable wear plate made from fibre-glass reinforced plastic

Centrifugal submersible sewage pumps fitted with the MultiCut cutting system are used as stationary appliances for backpressure protection of detached houses. They are suitable for pumping domestic wastewater with the usual additions (as specified in German standard DIN 1986, Part 3).

For pumping from ducts which are connected to the public sewer system, explosion-proof submersible pumps of have to be used. On account of the upstream cutting system, the pressurised line as from DN 32 - as from DN 80 minimum without cutting system - may be routed parallel to the terrain.

Operating conditions up to a temperature of the material to be transported of 40° celsius, submerged motor: continuous operation (S1), emerged motor: intermittent operation (S3) (e.g. 35% = 3.5 min. operation, 6.5 min. break).

The unique MultiCut cutting system ensures a maximum of operational safety at outstanding delivery characteristics. Fitted with a cutter plate made of hardened stainless steel and a three-bladed knife, it disintegrates coarse additions in the wastewater with more than 200,000 cutting processes per minute before they can get into the pump hydraulics. Solids which cannot be transported are rejected outside of the pump by the cutting rotor as the cutting system is located upstream from the pump hydraulics. Specifically arranged grooves on the cutter plate ensure additional safety as the cutting unit is permanently cleaned automatically during the delivery.

Pump ready for connection according to EN 12050 with 10 m cable and CEE plug 16 A (type M + MS) or schuko plug (type ME + MES). Ex II 2 G Ex db IIB T4 Gb

For pumps with automatic switch control, the pump base are included in delivery. As Ex-pump with 10 m cable without plug. Complete motor protection only in connection with appropriate controls units (see accessories).

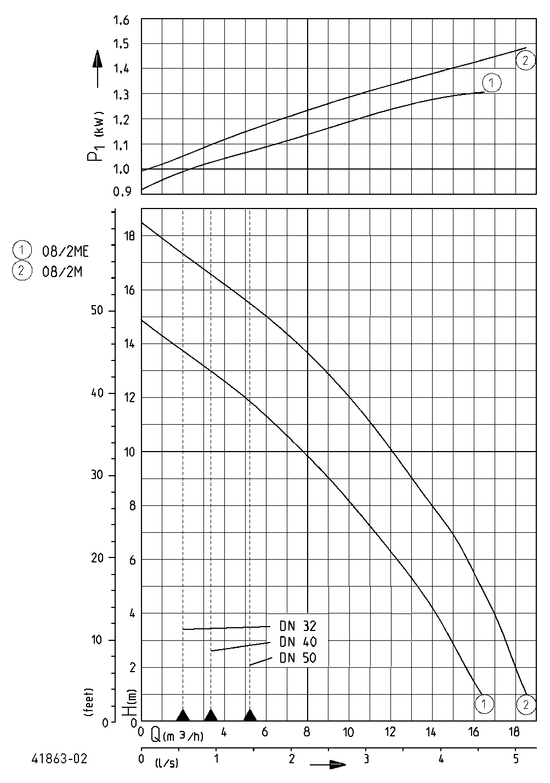

| Delivery head Hmax | 18 m |

| Flow rate Qmax | 18 m³/h |

Specifications can be changed without notice. Performance subject to ISO 9906 tolerances.

The minimum flow velocity in the pressure piping must be 0.7 m/s according to EN 12056.

This data is represented in the performance curve as a limit of application.

5 results

| Type | Code No. | Ciruit | Voltage | Motor rating P1 | Motor rating P2 | Current | Motor protection | Plug | S3 | Motor housing |

|---|---|---|---|---|---|---|---|---|---|---|

JP50342 | Without level control | 1/N/PE~230 V | 1.37 kW | 0.98 kW | 6 A | In motor | Safety | 10 % | Stainless steel | |

JP50344 | Without level control | 3/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | In motor | CEE-16A | 10 % | Stainless steel | |

JP50346 | Without level control | 3/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | With control unit | Without | 35 % | Grey cast iron | |

JP50343 | With built-in level control | 1/N/PE~230 V | 1.37 kW | 0.98 kW | 6 A | In motor | Safety | 10 % | Stainless steel | |

JP50345 | With built-in level control | 3/PE~400 V | 1.65 kW | 1.24 kW | 2.8 A | In motor | CEE-16A | 10 % | Stainless steel |