How does a submersible pump work?

A submersible pump for domestic use is a centrifugal pump. It is suitable for pumping lightly polluted water, also called grey water. Grey water is domestic dirty water without faeces.

A rotating impeller sets the water entering the pump housing in motion. The pump is driven by an electric motor integrated watertight into the housing. Due to the high speed of approx. 3,000 rpm, the spirally arranged paddles push the water to the outlet of the wastewater pump housing. A pressure pipe or hose is connected to this.

Depending on the drive power and size of the paddle wheel, also called impeller, a certain flow rate of water can be pumped to different heights and distances.

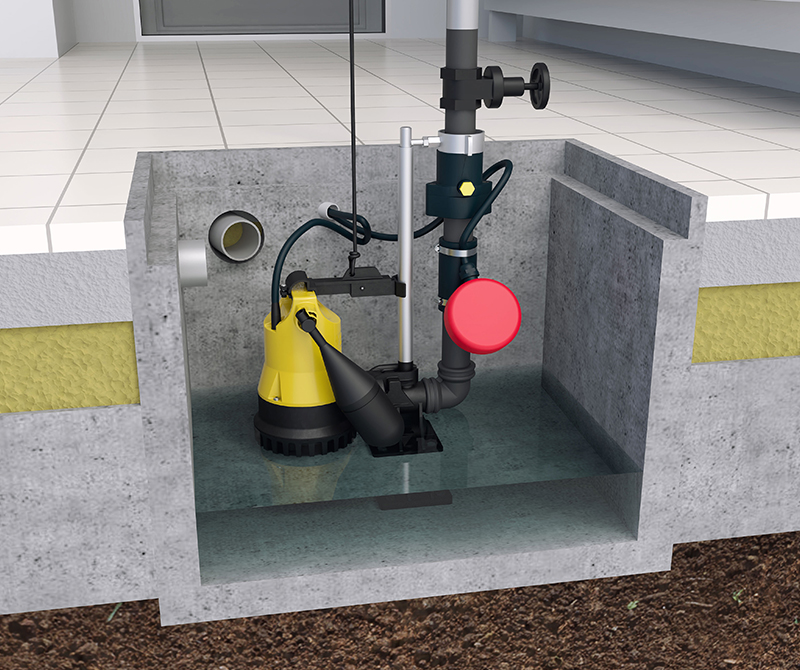

A submersible pump is switched on either by a float switch mounted directly on the housing or by an external control unit. Depending on the inflow of dirty water into the tank in which the pump is located, the movable float floats up. If the water level rises to the switch-on point, an internal microswitch activates the pump's drive motor. When the minimum water level is reached, it is immediately switched off again. The circuit is switched on and off directly in single-phase 230 V submersible pumps for domestic use, as the electrical power is relatively small.

Unlike centrifugal pumps for fresh water supply, whose internal components have a narrow-gap design to achieve high pressures and work with several impellers in succession, a sewage pump has only one impeller. The pressure that can be measured at maximum output is therefore normally no greater than, for example, 1 bar. This corresponds to a delivery head of 10 metres.

Dirty water can contain sand, fibres, hair and other solid particles. In order for these components to be conveyed safely through the pump casing, there must be a sufficiently large gap between the casing and the impeller. This gap determines the so-called free passage. For wastewater pumps that can be used to prevent backwater in buildings, this must be 10 mm. This means that a ball of 10 mm diameter must not lead to a blockage of the impeller when passing through the pump casing.

The diameter of the connected pipe must not be smaller than the dimension of the pipe connection on the casing in the case of dirty water pumps. This prevents solids from moving through the pump but later getting stuck in the pipe that is too narrow.

A good wastewater pump, which typically operates for only a few minutes a day, is not characterised by particular energy efficiency. What is important is a high level of operational reliability when dealing with solids, hair and fibres, such as those that enter the collection tank from washing machines or dishwashers, showers or sinks.

Dirty water submersible pumps for backwater protection of residential buildings normally have an electrical output of 300 - 800 W. This is sufficient to quickly dispose of the typical amount of water from the collection tank in the basement. The maximum delivery head of the pump is normally greater than necessary to convey the dirty water above the backflow level into the sewer. However, a power reserve is necessary to overcome friction losses of the flowing water in the different lengths of pressure pipe. In principle, the following applies to centrifugal pumps: the higher the back pressure in the pipe, the lower the flow rate.

Of course, submersible pumps can also be used for applications other than sewage disposal as part of backwater protection. Mobile use, such as for pumping out swimming pools, fish ponds and rain barrels, is also possible. It is also intended for use in the event of flooding of cellars or shafts. For all types of use, however, the nature of the water to be pumped must always be taken into account. Chemicals such as chlorine or salts can lead to corrosion. The housings and internal parts of high-quality motor-driven submersible pumps are made of resistant materials such as stainless steel and glass-fibre reinforced plastics, but metal corrosion can still occur if the pump is exposed to aggressive acidic dirty water for a long time.

Sand particles in the water are abrasive and lead to excessive wear on the impeller blades or the seals of the rotating motor shaft. This means loss of power, longer running times and increased power consumption. In the worst case, the pump will fail if water gets into the motor compartment through defective seals. It is therefore important to check dirty water pumps regularly. This applies especially to permanently installed submersible pumps in wastewater tanks, as these do their work hidden away and often protect cellar rooms against backwater.

Higher water temperatures of more than 40°C are also not permissible. The integrated electric motor of the submersible pump is surrounded by water in a stainless steel housing. It is therefore cooled during pumping. The warmer the water, the less the cooling. The maximum running time of the pump is then lower because the integrated safety thermostat switches off the motor if it overheats. Once this happens, the pump will not start again until the motor has cooled down again. You can also find helpful information on the topic of submersible pumps on our Induux manufacturer page or the Induux Wiki.

When purchasing a submersible wastewater pump, pay particular attention to quality and durability. Experience shows that permanently installed submersible pumps are used in buildings for a very long time without being serviced at regular intervals. If they fail, this may result in backwater, basement flooding and consequential damage to inventory and building technology.