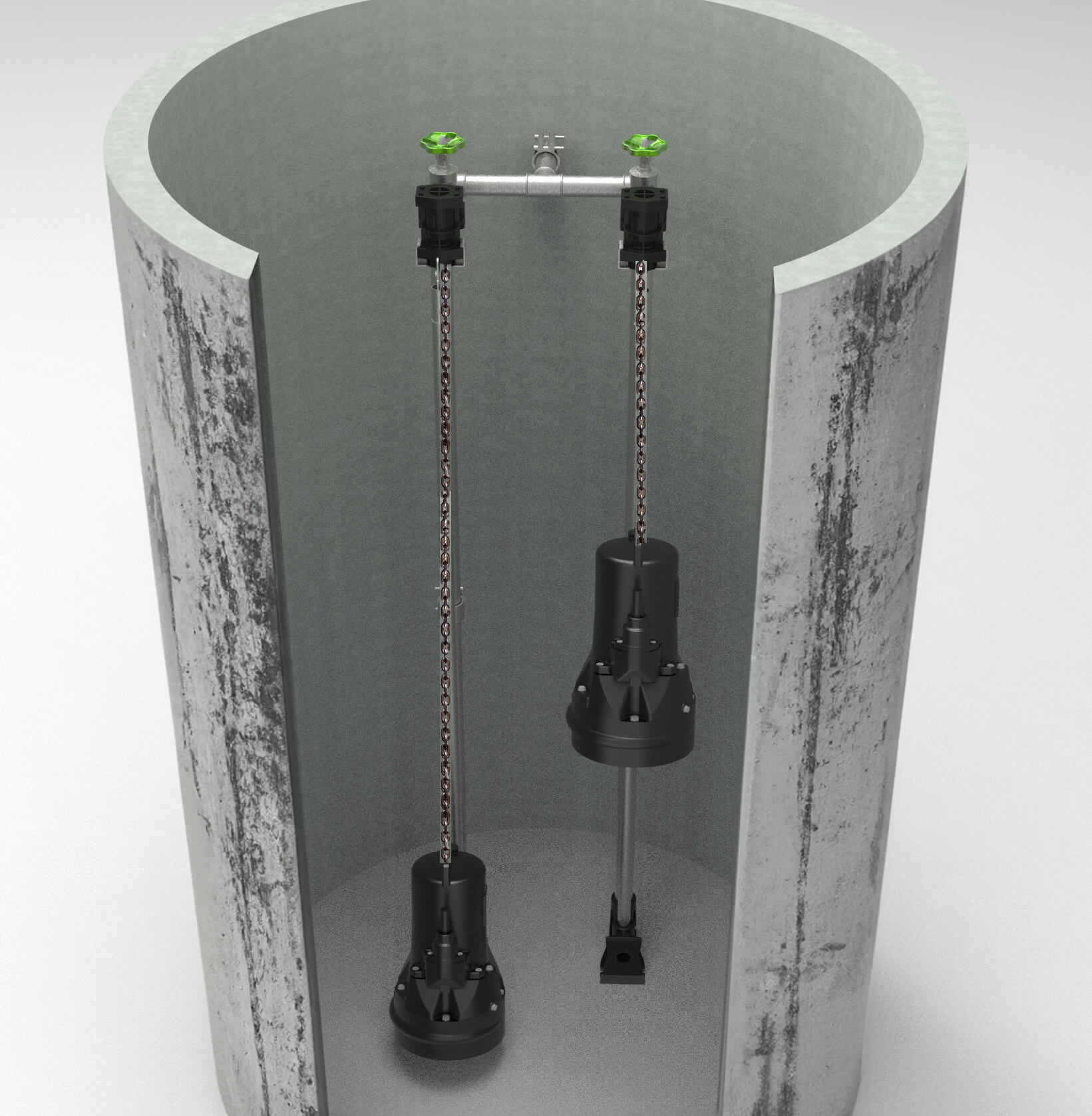

Pumps and valves in pressure drainage systems are important components for disposing of wastewater easily and cost-effectively to the sewage treatment plants, especially in urbanized areas. They are often installed in concrete sumps, where they are exposed to influences that can severely affect the material and impair their function. With the new DN 40 Installation Set, Jung Pumpen is launching a simple mounting device for wastewater pumps that allows one or two pumps to be installed quickly. Stainless steel and high-strength plastic also guarantee a very long service life for the new Installation Set.

Corrosion of aged sump internals

Not only these components are exposed to aggressive environmental influences, but also the pump itself is often affected. Hydrogen sulfide (H2S), which can form in wastewater during long periods of standing, leads to the formation of sulfuric acid. This acid causes metal parts of pumps and fittings to corrode and also affects concrete sumps. Sand and other sediments in the wastewater lead to erosion and wear of the components. Also, pump vibration can cause joints to leak and pumps to operate inefficiently. Without regular maintenance of the pump and its mounting equipment, minor problems can become major ones and complete failure is imminent. Biological growth on the components and permanent temperature fluctuations within the sump structure are additional influencing factors.

Jung Pumpen Installation Set DN 40 for fast renovation

The factors mentioned above show that especially older sump installations of pressure drainage pumps should be replaced. Often, cast iron components are still installed here, which show corrosion and thus the tightness of the connections is no longer guaranteed.

The Installation Set DN 40 from Jung Pumpen has been specially developed to solve the above-mentioned problems. It is installed in the sump and connected to an existing DN 40 pressure pipe on site. As of now, the DN 40 Installation Set can be extended to also renovate duplex pump stations in a short period of time. The advantages speak for themselves:

1. Quick installation: the pre-assembled parts make installation much easier. This not only saves time, but also reduces work costs.

2. Long-lasting materials: the use of high-quality materials, such as high-strength stainless steels and glass-fiber-reinforced plastics, ensures a longer service life for the installation set and reduces the need for frequent repairs or spare parts.

3. Flexibility: The installation set is suitable for both single and double installations. This provides installers with flexibility, depending on the specific requirements of the construction site.

4. Compatibility: Compatibility for all sewage pumps of the MultiCut range is another advantage that facilitates integration into existing systems.

The impact on the business

With simple renovation solutions like these, Jung Pumpen is setting new standards in the wastewater industry. Companies can increase the efficiency of their pumping equipment, maintain its value and prevent malfunctions at the same time. Such solutions are expected to become more common in the coming years to meet the growing demands of the branch.